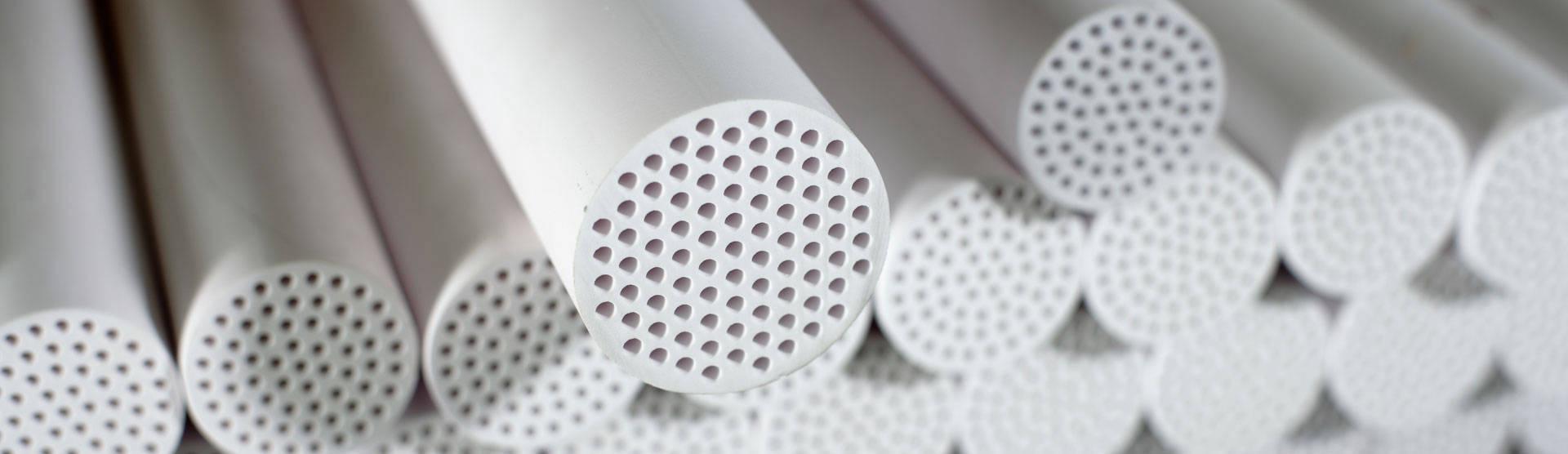

Ceramic membrane filtration is a physical separation process that uses ceramic materials with porous structures to separate particles, microorganisms, and dissolved substances from liquids. Unlike traditional filtration materials like polymers, ceramic membranes are known for their high chemical stability, durability, and resistance to high temperatures, making them ideal for demanding applications in various industries.

What are the key advantages of ceramic membrane filtration?

Ceramic membranes offer several significant advantages:

High Durability: Ceramic membranes are highly resistant to abrasion, fouling, and harsh chemical environments. This durability extends their lifespan and reduces maintenance costs.

High Temperature and Pressure Resistance: Ceramic materials can withstand extreme temperatures (up to 1000°C) and pressures, which makes them suitable for processes that require these conditions.

Chemical Stability: They are resistant to a wide range of chemicals, including acids, alkalis, and solvents, enabling them to perform well in challenging environments.

Reduced Fouling: Ceramic membranes exhibit less fouling than polymeric membranes, improving filtration efficiency and reducing the frequency of cleaning.

Reusability: Due to their robust nature, ceramic membranes can often be cleaned and reused multiple times, providing a sustainable and cost-effective solution.

In which industries are ceramic membrane filtration technologies commonly used?

Ceramic membrane filtration is applied across a variety of industries:

Water and Wastewater Treatment: Ceramic membranes are used to purify drinking water, treat industrial wastewater, and desalinate brine. Their high filtration precision allows them to remove fine particles, bacteria, and other contaminants from water sources.

Food and Beverage Industry: Ceramic membranes are used for separating proteins, bacteria, and yeast in processes like beer and wine filtration, as well as for dairy processing such as milk clarification and whey protein isolation.

Pharmaceuticals and Biotechnology: In pharmaceutical production, ceramic membranes provide a sterile filtration solution for biologics, vaccines, and other injectable products. They are also used in the concentration and purification of bioproducts.

Oil and Gas Industry: Ceramic membrane filtration is utilized for separating oil-water emulsions, removing particulates from crude oil, and other processes that require high-temperature and high-pressure environments.

Chemical Industry: Ceramic membranes are used in chemical processes such as solvent recovery, acid recovery, and purification of specialty chemicals.

How does ceramic membrane filtration work?

Ceramic membrane filtration works by forcing liquid through a porous ceramic membrane under pressure. The membrane acts as a barrier, allowing only specific molecules or particles to pass through based on size, charge, and other factors. There are several types of ceramic membrane filtration, including microfiltration, ultrafiltration, and nanofiltration, each designed for different filtration applications based on pore size. The process typically involves:

Feedwater Introduction: The liquid is pumped through the ceramic membrane system under pressure.

Separation: As the liquid passes through the membrane, contaminants larger than the membrane pores are retained on the surface, while purified water or liquid permeates through.

Concentration and Cleaning: The retained contaminants can be periodically removed or concentrated, and the membrane can be cleaned using chemical agents or backflushing techniques.

What are the challenges associated with ceramic membrane filtration?

While ceramic membrane filtration offers many benefits, there are some challenges:

High Initial Cost: Ceramic membranes are often more expensive upfront than polymeric membranes, which can be a barrier for some smaller companies or projects.

Fouling and Cleaning: Although ceramic membranes have a higher resistance to fouling, they still require periodic cleaning, especially in applications with highly viscous fluids or complex feedwater. Cleaning methods must be carefully selected to avoid damaging the membrane.

Energy Consumption: The high pressures required for filtration can lead to significant energy consumption, particularly in large-scale industrial processes.

Handling and Installation: Ceramic membranes are brittle and can be fragile during handling and installation, which necessitates careful management to avoid damage.