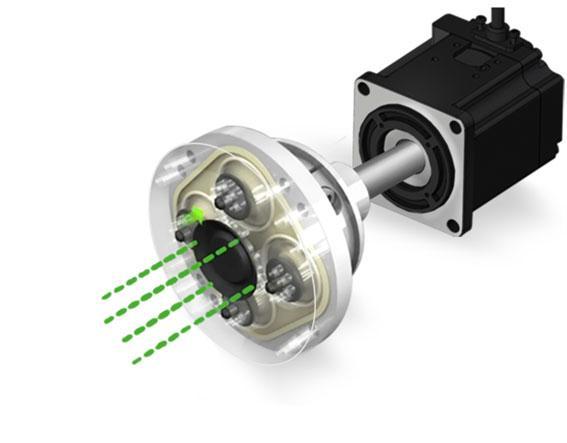

A four-piston diaphragm pump is a positive displacement pump that uses four pistons to move fluid through a diaphragm system. The pump works by creating pressure that forces the diaphragm to expand and contract, which in turn moves the fluid through the pump. These pumps are highly efficient and capable of handling a wide range of fluids, including thick, viscous, and abrasive substances.

The operation of a four-piston diaphragm pump involves the movement of pistons connected to diaphragms. As the pistons move back and forth, they create suction on one side of the diaphragm and pressure on the other. This action causes the diaphragm to flex, pushing the fluid through the pump. The four pistons work together to provide a smooth and continuous flow of fluid, making the pump ideal for high-pressure applications.

What Are the Typical Applications of Four-Piston Diaphragm Pumps?

More questions to solve?

More Questions

More Questions

[VIRTUAL Address] HOLVES Su310 intelligent stainless steel fermenter is a new generation of pilot and small-scale production equipment, integrating hardware innovation and intelligent control. In the pharmaceutical industry, stainless steel fermenters are crucial for produ...

[Ceramic Membrane Filtration] Ceramic membrane filtration is a physical separation process that uses ceramic materials with porous structures to separate particles, microorganisms, and dissolved substances from liquids....

[Tangential Flow Filtration] The Application of Tangential Flow Filtration Cassettes...

[Four-Piston Diaphragm Pumps] What is a Four-Piston Diaphragm Pump? How Does a Four-Piston Diaphragm Pump Work? What Are the Key Advantages of Four-Piston Diaphragm Pumps?...

[Photobioreactor] Photobioreactors are specialized cultivation systems designed to grow photosynthetic microorganisms such as microalgae, cyanobacteria, and other photosynthetic cells under controlled environmental conditions. Lab-scale photobioreactor systems serve as...

[Fermenters] Optimizing Fermenters for Enhanced Production...

[Bioreactors] Biological Reactions in Bioreactors: Advanced Solutions for Efficient Fermentation...

[Tangential Flow Filtration] Tangential Flow Filtration (TFF) is a separation process widely used in various industries, especially in biopharmaceutical manufacturing, water treatment, and chemical processes....

[Small Spray Dryers] Learn the Basics of Small Spray Dryers...

[Fermenter] You can find the answer to the question about fermenter feed supplement……...