Specialized in Cell Culture Process Development

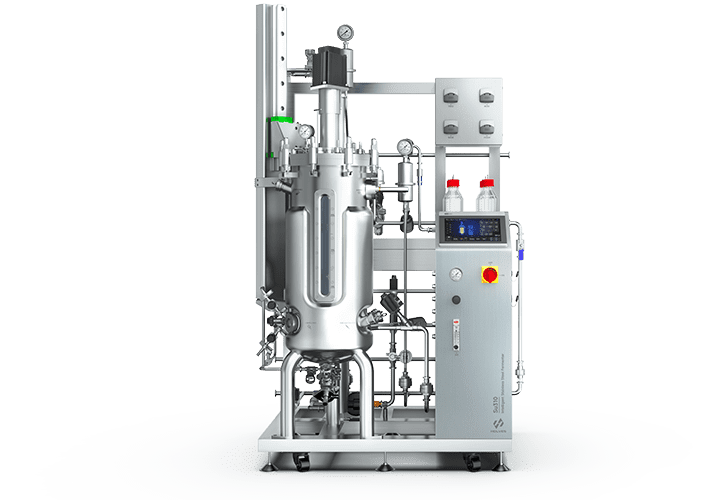

HOLVES Omini Cell510 Series all-purpose Bioreactor, focused on cell culture process development, centers on a stainless steel intelligent platform. It is dedicated to providing standardized solutions that combine high cost-effectiveness with exceptional flexibility for process development, pilot-scale upscaling, and GMP clinical sample production stages.

It deeply integrates forward-thinking design with local lean manufacturing, not only providing stable and reliable process support throughout cell culture via high-precision automation systems, but also leveraging a modular architecture to flexibly adapt to future process pathway expansion and upgrade requirements. From fundamental parameter control to compatibility with complex process scenarios, the Omini Cell510 achieves precise alignment between equipment and processes through highly scalable hardware configurations and intelligent control logic.

Applications

Biopharmaceuticals

Biochemistry

Food Chemical

Cell Culture

Fine Chemical Engineering

Microorganism

HIGHLIGHTS

High Cost Effective

- Long-term economic efficiency with no ongoing consumable costs: Constructed from 316L stainless steel, with material-contact surfaces treated by both mechanical and electrolytic polishing. A single investment ensures decades of reuse, making it the more economical choice for large-scale, commercial production.

- Mature Domestic Platform: Drawing on internationally advanced design concepts and integrating localized manufacturing and services, we ensure stable and reliable equipment performance while offering rapid after-sales response and more competitive pricing.

Flexible Expansion

Security Guarantee

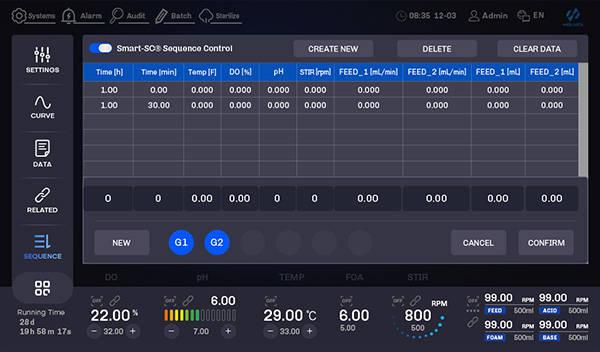

HF-Control v3.0 Holographic Intelligent Control System

HOLVES 3.0 Holographic Intelligent Control System, which integrates the sense of design and practicability, realizing a leapfrog upgrade.

- Automotive-grade UI Design: The interface adopts a dark theme, with a centralized minimalist design and layered architecture, presenting the complex process data in a more intuitive and multi-dimensional way.

- Dual-screen Synergy: Main screen integrated operation control interface, support multi-level menu view. The bottom of the fixed sub-screen display, the core data visualization area, real-time dynamic display of key parameters trends.

- Safe and Compliant Data Management: It supports data export, has built-in multi-level permission management, requires authorization for critical operations, meets GMP data traceability requirements.

- Multi-Parallel Fermenter Synergy Control: For complex systems such as multi-parallel fermenters and cascade fermenters, it supports one-key switching between single vessel and multi-vessel modes, with a unified operation interface.

Product Display

All-PURPOSE Stainless Steel Bioreactor

| Product model | Omini Cell510-30L | Omini Cell510-50L | Omini Cell510-100L | Omini Cell510-200L | Omini Cell510-300L | Omini Cell510-500L | Omini Cell510-1000L | Omini Cell510-2000L | |

| Vessel volume | 30L | 50L | 100L | 200L | 300L | 500L | 1000L | 2000L | |

| Working volume | 8-24L | 12-40L | 25-80L | 40-160L | 80-240L | 100-400L | 200-800L | 400-1600L | |

| Material (inner) | inner vessel: AISI 316L stainless steel mirror polishing | ||||||||

| Material (outer) | vessel outer wall and jacket: AISI 304 stainless steel | ||||||||

| Manufacturing STD | ASME BPE-2019, PED certification standards | ||||||||

| Polishing | product contact: mechanical polish to Ra≤0.4µm | ||||||||

| Stirring power | Leadshine, PID control | ||||||||

| Stirring speed | 20-800±1 | 20-400±1 | 20-300±1 | ||||||

| Stirring impeller | Propeller type stirrer / Rotary Filter / Basket Impeller / Up-pumping Impeller | ||||||||

| Temperature control | PT100, PID control, Temperature regulation is accomplished by plate heat exchangers/ electrically heated jackets and cooling water. | ||||||||

| Heating form | Temperature control jacket | ||||||||

| Temperature range | Ambient temperature above 5-60℃, measuring range 0-150℃, accuracy ±0.1℃, resolution 0.01 | ||||||||

| pH | 0-14, precision ±0.02, resolution 0.01, PID control, Done under the control of acid / base pumps or CO2 mass flow meters | ||||||||

| DO | 0-100% O2 Saturation, precision ≤±(1%+6ppb), resolution 0.01, PID control | ||||||||

| Aeration method | Surface aeration | ||||||||

| Filter | Pre-filtration 0.2μm, Fine filtration 0.01μm, PTEF, Optional: heated jacket for the exhaust filter housing | ||||||||

| Exhaust condenser | AISI 316L / AISI 304L stainless steel | ||||||||

| Peristaltic pump | Standard 4 units, PID interlocking control, foam / feed / acid / base, feed can be added | ||||||||

| Interfaces |

Inlet/Outlet Ports: inoculation valve ports, feed valve ports, online sampling ports, PAT spare interfaces, bottom valves, surface vents, deep vents, safety rupture discs/pressure relief valves. Probe Interfaces: Dedicated ports for monitoring pH, DO, level, pressure, foam, and other parameters. Operational status visualization windows and searchlights. Supports customization |

||||||||

|

Automatic high-pressure steam sterilization Standard |

Automatic Lid Lifting Standard |

Automatic Vessel Pressure Standard |

The Integrated Vessel Bottom Valve Standard |

CIP Automatic Cleaning Option |

|

Multiple Vessel Modular Expansion Option |

Vessel Weighing Module Option |

Feeding Weighing Module Option |

PAT Process Detection Extension Option |

Support Customized Functions Option |