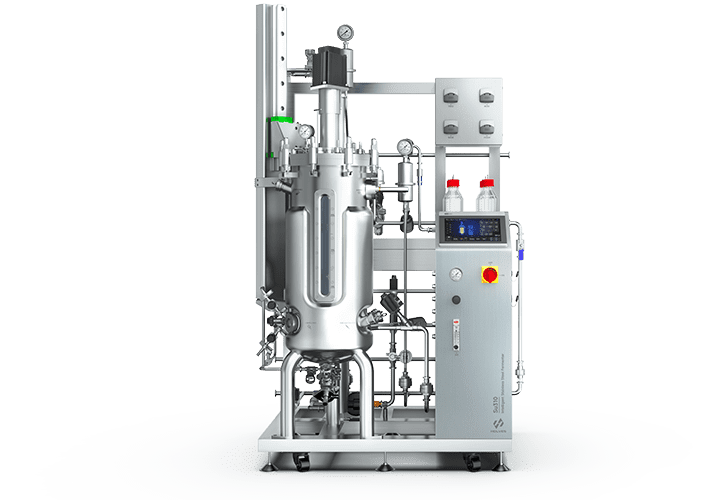

Stainless steel fermenter for pilot-scale fermentation

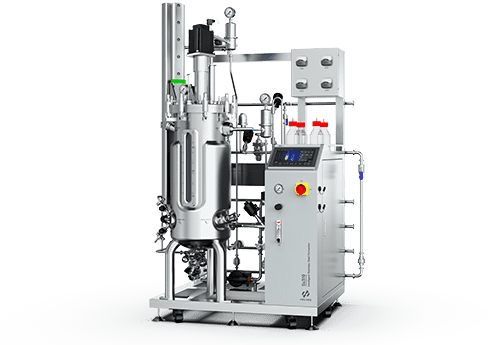

HOLVES Su310 intelligent stainless steel fermenter is a new generation of pilot and small-scale production equipment, integrating hardware innovation and intelligent control.

Su310 is highly scalable and customizable for diverse scenarios. From the pharmaceutical industry's stringent GMP compliance upgrades, to the integration of PAT process testing, feeding system, tail gas analysis module, to the optimization of vessel structure and control logic for process adaptation, HOLVES can provide in-depth personalized solutions, so that the equipment can be precisely matched with your process.

Applications

Biopharmaceuticals

Biochemistry

Food Chemical

Cell Culture

Fine Chemical Engineering

Microorganism

HIGHLIGHTS

Structure Upgrade

- Servo Motor Drive: For vessels of 50L and below, servo motors are used to replace the traditional drive method.

- Double Filtration Protection: The inlet and exhaust air pipes are equipped with high-efficiency sterilizing filters, building a double barrier of sterility.

- Automatic Lid Lifting: Automatic lid lifting device is standard for 30L and above models, support one-button electric opening and closing.

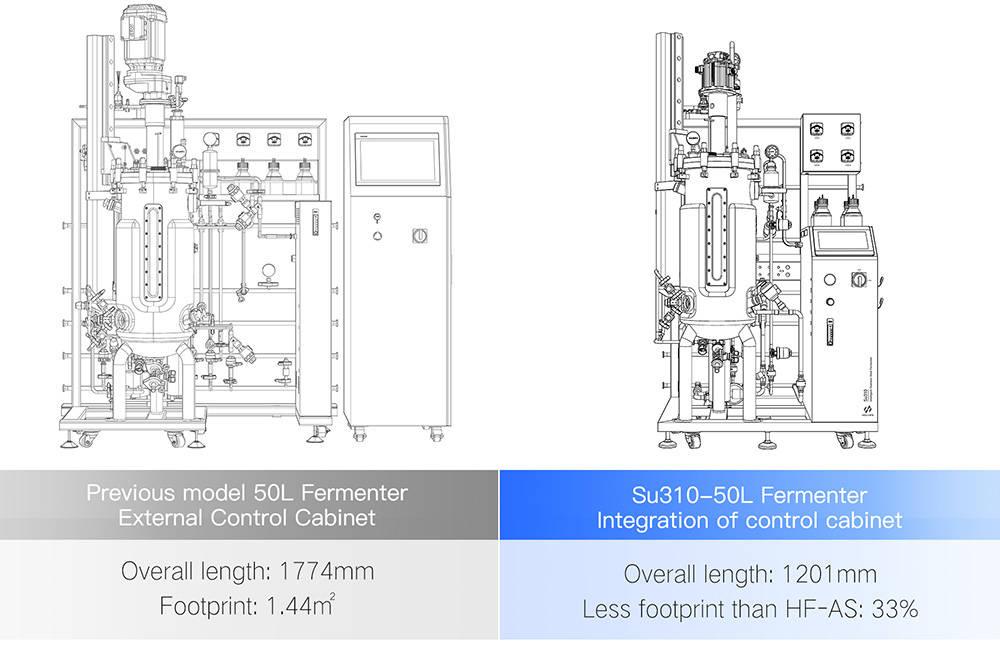

- Integrated Layout Optimization: The control system is fully integrated into the equipment skid, reducing the footprint by about 33% compared with its predecessor, and optimizing the utilization of space in the workshop.

Holistic Synchronization

- Can be built-in multiple sets of program templates and reserved expansion interfaces according to demand, users can expand according to process requirements, without the need for large-scale transformation of the main structure of the equipment or the core system. Support WinCC / SCADA.

- Supports cross-factory equipment group management, truly realizing one-screen control of the whole situation.

- Based on the Internet of Things (loT) system, key process parameters such as temperature, pH, DO, etc. are converged into the cloud database in real time, forming a complete data chain.And it provides accurate data support for subsequent AI process optimization and remote decision-making, and helps transition from experience-driven to data-driven.

- Equipped with HOLVES Meta-Tri® Audit Trail System, which automatically records the whole process operation log, and the experimental process can be tracked.

- Real-time encrypted data storage, supporting multi-level permission management, to prevent data leakage or tampering, and meet the GMP / GLP and other data integrity requirements.

- HMI built-in independent audit trail module.

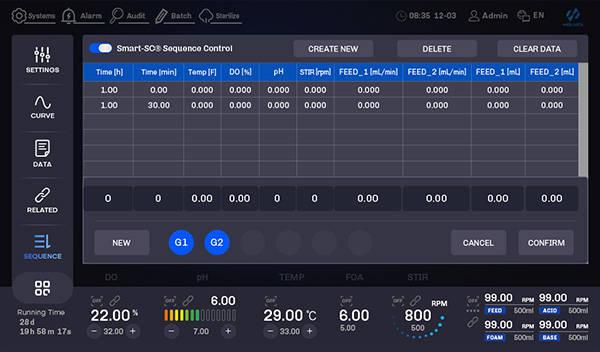

- Equipped with HOLVES Smart-SC® Intelligent Sequential Control System, supports unlimited customization of multi-stage process parameters, accurately matching the needs of each stage of fermentation.

- Automated operation of the whole process, lowering operational errors.

- The control logic can be flexibly adjusted according to the process selection to meet the whole cycle of adaptation from R&D to production.

Module Expansion

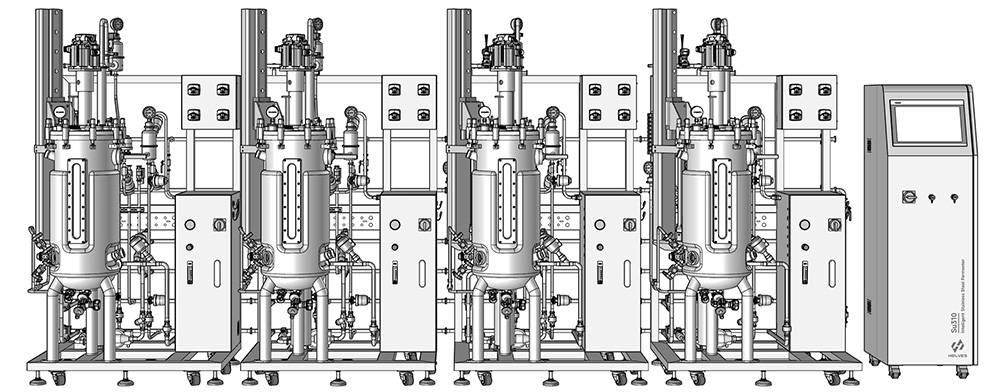

Unique modular design, a single vessel can be easily expanded into a cluster of seed tanks, and the parallel connection of multiple vessels is as convenient as building blocks, which realizes flexible capacity growth without the need for shutdowns and modifications. As shown in the figure below: the technical schematic / equipment layout for the Su310-50L Quad Fermentation System is presented.

Based on HOLVES intelligent platform real-time monitoring and analysis of fermenter operation data, early warning of potential failures, maximizing the protection of production continuity.

HF-Control v3.0 Holographic Intelligent Control System

HOLVES 3.0 Holographic Intelligent Control System, which integrates the sense of design and practicability, realizing a leapfrog upgrade.

- Automotive-grade UI Design: The interface adopts a dark theme, with a centralized minimalist design and layered architecture, presenting the complex process data in a more intuitive and multi-dimensional way.

- Dual-screen Synergy: Main screen integrated operation control interface, support multi-level menu view. The bottom of the fixed sub-screen display, the core data visualization area, real-time dynamic display of key parameters trends.

- Safe and Compliant Data Management: It supports data export, has built-in multi-level permission management, requires authorization for critical operations, meets GMP data traceability requirements.

- Multi-Parallel Fermenter Synergy Control: For complex systems such as multi-parallel fermenters and cascade fermenters, it supports one-key switching between single vessel and multi-vessel modes, with a unified operation interface.

Product Display

SMART Stainless Steel Fermenter

| Product model | Su310-10L | Su310-30L | Su310-50L | Su310-100L | Su310-200L | Su310-300L | Su310-500L | Su310-1000L | Su310-2000L |

| Vessel volume | 10L | 30L | 50L | 100L | 200L | 300L | 500L | 1000L | 2000L |

| Working volume | 3-8L | 8-24L | 12-40L | 25-80L | 40-160L | 80-240L | 100-400L | 200-800L | 400-1600L |

| Material (inner) | inner vessel: AISI 316L stainless steel mirror polishing | ||||||||

| Material (outer) | vessel outer wall and jacket: AISI 304 stainless steel | ||||||||

| Manufacturing STD | ASME BPE-2019, PED certification standards | ||||||||

| Polishing | product contact: mechanical polish to Ra≤0.4µm | ||||||||

| Stirring power | Leadshine / Panasonic / SEW Geared motor, PID control | ||||||||

| Stirring speed | 20-800±1 | 20-600±1 | 20-400±1 | 20-300±1 | |||||

| Stirring impeller | Inclined-blade / Marine Propeller / paddle-type / turbine impeller / propulsion mixing paddles, etc. | ||||||||

| Temperature control | PT100, PID control, Temperature regulation is accomplished by plate heat exchangers/ electrically heated jackets and cooling water. | ||||||||

| Heating form | Temperature control jacket | ||||||||

| Temperature range | Ambient temperature above 5-60℃, measuring range 0-150℃, accuracy ±0.1℃, resolution 0.01 | ||||||||

| pH | 0-14, precision ±0.02, resolution 0.01, PID control, Done under the control of acid / base pumps or CO2 mass flow meters | ||||||||

| DO | 0-100% O2 Saturation, precision ≤±(1%+6ppb), resolution 0.01, PID control | ||||||||

| Flow regulation | Imported glass rotor flowmeters, Air, Supports additional CO2 / O2 / N2 and multi-gas ventilation, supports upgrading to MFC thermal mass flow meter | ||||||||

| Gas distributors | Annular distributor / Microporous diffuser | ||||||||

| Filter | Pre-filtration 0.2μm, Fine filtration 0.01μm, PTEF, Optional: heated jacket for the exhaust filter housing | ||||||||

| Exhaust condenser | AISI 316L / AISI 304L stainless steel | ||||||||

| Peristaltic pump | Standard 4 units, PID interlocking control, foam / feed / acid / base, feed can be added | ||||||||

| Interfaces |

Inlet/Outlet Ports: inoculation valve ports, feed valve ports (with off-position probes, four-valve manifolds, etc.), online sampling ports, PAT spare interfaces, bottom valves, surface vents, deep vents, safety rupture discs/pressure relief valves. Probe Interfaces: Dedicated ports for monitoring pH, DO, level, pressure, foam, and other parameters. Operational status visualization windows and searchlights. Supports customization |

||||||||

|

Automatic high-pressure steam sterilization Standard |

Automatic Lid Lifting Standard |

Automatic Vessel Pressure Standard |

The Integrated Vessel Bottom Valve Standard |

CIP Automatic Cleaning Option |

|

Multiple Vessel Modular Expansion Option |

Vessel Weighing Module Option |

Feeding Weighing Module Option |

PAT Process Detection Extension Option |

Support Customized Functions Option |

Product Brochure

Product Brochure

Compared with its previous generation, Su310 achieves breakthrough structural optimization by fully integrating the control system into the fermenter skid, avoiding the traditional external control cabinet and significantly reducing the footprint. 50L and below models are equipped with a high-performance servo motor drive system as standard, which delivers far greater mixing precision, smooth operation and quietness than traditional ones.