About Microcarrier

-

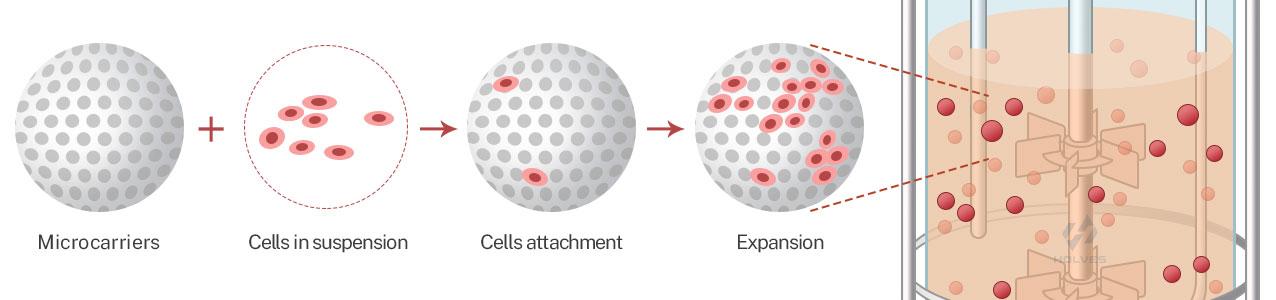

Microcarrier (Microcarrier) means a class of microspherical scaffolds with a diameter of 50-350 μm and a density slightly higher than that of water, which have biological functions such as cell culture, proliferation and delivery. During the process of cell value-added differentiation, it can adhere to cells and provide a support matrix for cells.

-

HOLVES develops and produces a wide range of cell culture carriers, including not only dextran-based microcarriers (HCD-001 and HCD-001G), but also biodegradable soluble 3D carriers (HCD-003) and polyester fiber carriers (HCF-001 and HSD-001) to meet the user's individual needs in the cell culture and purification process, and to facilitate the innovative development of the biopharmaceutical industry.

Microcarriers of different materials

The most common classification of microcarriers is based on materials, including dextran microcarriers, gelatin microcarriers, cellulose microcarriers, polystyrene microcarriers, chitosan microcarriers, polyurethane foam microcarriers, alginate gel microcarriers, magnetic microcarriers and other microcarriers. And because these raw materials can be formed into a variety of different shapes, and can be classified according to the shape of the common spherical, flaky, fibrous, tubular, microporous and so on.

- Dextran microcarriers: Almost all animal cells that can be adhered to the wall in vitro can adhere to these microcarriers.

- Gelatin microcarriers: suitable for wall-dependent cells and suspension culture cells, such as human bone marrow mesenchymal stem cells.

- Cellulose microcarriers: suitable for wall-dependent cells and suspension culture cells. Mainly used for the production of recombinant products and monoclonal antibodies by culturing CHO, BHK, NSO and hybridoma cells.

- Polystyrene microcarriers: more applied in fluidized bed perfusion culture of CHO cells, also can be used to culture adherent and semi-adherent cells.

- Polyester fiber microcarriers: carriers for mammalian cell monolayer culture.

There are also polyurethane foam microcarriers, alginate gel microcarriers, magnetic microcarriers, etc. These microcarriers play an important role in the field of biotechnology due to their different physical and chemical properties, which can support the attachment and growth of different types of cells. When selecting microcarriers, comprehensive consideration should be made based on specific cell types, culture conditions, and costs.

HCD-001 Spherical Microcarrier(HCD-001G)

HCD-001 microcarrier is a high-performance microcarrier made from dextran microspheres coated with animal-free recombinant collagen, significantly enhancing cell attachment efficiency and proliferation rate. It is particularly suitable for large-scale expansion of hard-to-culture cells (such as MSCs, Vero, MRC-5, 2BS, etc.) under serum-free culture conditions and is fully compatible with existing microcarrier-based cultivation processes.

The HCD-001G microcarrier undergoes gamma irradiation sterilization and is packaged in PC containers equipped with specialized transfer conduits to ensure sterility, meeting the stringent requirements of high-standard biological laboratories.

- Gentle and Efficient Harvesting: The easily hydrolysable surface recombinant collagen protects cell viability and ensures membrane integrity.

- Full System Compatibility: Compatible with various bioreactor systems, including stirred-tank, single-use reactors, and shake flasks, providing ample surface area for cell growth.

- High-Density Cultivation: Ultra-large surface area maximizes cell density.

- Flexible Process Support: Efficient separation technology allows easy isolation of cultures and cells from the medium, facilitating product collection. Perfectly suited for perfusion and continuous fed-batch cultures.

- Seamless Scale-Up Production: Supports scale-up processes for cell culture, including digestion-transfer or direct expansion strategies.

HCD-003 Soluble 3D Microcarrier

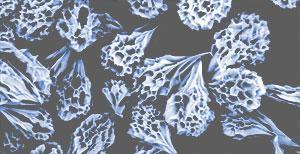

Its dry particle size ranges from 150–300 μm, with internal macropores of 20–50 μm (specific surface area ≥ 9000 cm²/g), providing a stable microenvironment for cell growth. Its natural biocompatibility supports high-density cultivation of conventional cells and significantly enhances the efficiency of hard-to-attach cells, making it a versatile solution in cell culture.

HCD-003 soluble 3D microcarrier are not only suitable for high-density culture of conventional cells, but also for cell types that are difficult to grow against the wall, making them a versatile and efficient choice for cell culture.

- 3D Structural Advantage: Unique 3D structure supports serum-free or low-serum culture of hard-to-attach cells (e.g., MSCs, MRC-5, Vero).

- High-Density Cultivation: Achieves over twice the density of MSCs compared to traditional dextran microcarriers.

- Efficient Recovery: The soluble 3D microcarriers are completely degradable by trypsin/collagenase, with a recovery rate of >90%.

- Broad Application Scope: Suitable for cell therapy, exosome production, biopharmaceuticals, vaccine manufacturing, and cultivated meat industrialization.

Carrier Info

| Name | Type | Size | Number | Postscript |

|

HCD-001 Spherical Microcarriers |

HCD-001 HCD-001 HCD-001 HCD-001 |

25g 50g 250g 1000g |

HCD001-001 HCD001-002 HCD001-003 HCD001-004 |

|

|

HCD-001G Spherical Microcarriers Microcarriers are gamma sterilized |

HCD-001G HCD-001G HCD-001G |

150g 600g 3000g |

HCD001G-001 HCD001G-002 HCD001G-003 |

Microcarriers are gamma sterilized. They are sterilized before being put into the preparation process, so the user does not need to perform additional cleaning or autoclaving steps. Customized loads are available upon request. |

|

HCD-003 Soluble 3D Microcarriers |

HCD-003 HCD-003 HCD-003 HCD-003 |

1g 5g 10g 100g |

HCD003-001 HCD003-002 HCD003-003 HCD003-004 |

|