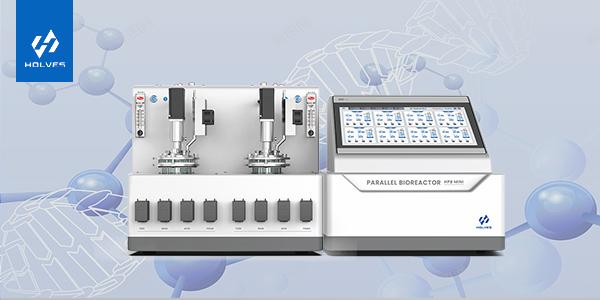

Parallel bioreactors enable the simultaneous preparation of multiple proteins or antibodies in one or more cell culture units through the simultaneous cultivation of two or more units of the same or different types. It has the following advantages over traditional cell culture:

1. Decrease production costs

Parallel bioreactors can significantly decrease cell culture costs. Within a unit, a cell culture system typically consists of a cell culture tank. The system consists of a series of cell culture units, each including a bioreactor and a centrifuge.

Each unit can be utilized multiple times depending on the type of product desired. In addition, since each unit has the same culture cycle, there is no need to set up additional reactors for amplification during the production process, which can greatly reduce production costs.

2、Improve culture efficiency

Compared with traditional cell culture, parallel bioreactor can greatly improve the efficiency of cell growth, and can significantly increase the yield of cell products. The ways of cell culture in parallel bioreactor mainly include batch replenishment culture, batch shake flask culture and batch fermentation.

3、Improve the environment of cell culture

When cells grow in liquid, they cannot move freely due to their sensitivity to the liquid environment, and the flow rate of the liquid stream also affects cell growth. Parallel bioreactor can change the liquid environment by changing the stirring speed, stirring direction and liquid flow direction, so as to improve the efficiency of cell growth and product production.

4、Increase product yield

Another important advantage of parallel bioreactors is the ability to increase product yields through differences in cellular metabolic pathways, thus better meeting the needs of different drugs and medical products. For example, some biopharmaceutical companies also use parallel bioreactors for antibody production. By adding two different types of antibodies to the same batch of medium, antibodies with different potencies are obtained, thus achieving the purpose of improving antibody potency, reducing production costs, minimizing side reactions and improving the stability of drug production. Due to the different requirements of biopharmaceutical companies for antibody drugs, parallel bioreactors have different advantages in different situations.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.

More questions to solve?

More Questions

More Questions

[VIRTUAL Address] HOLVES Su310 intelligent stainless steel fermenter is a new generation of pilot and small-scale production equipment, integrating hardware innovation and intelligent control. In the pharmaceutical industry, stainless steel fermenters are crucial for produ...

[Ceramic Membrane Filtration] Ceramic membrane filtration is a physical separation process that uses ceramic materials with porous structures to separate particles, microorganisms, and dissolved substances from liquids....

[Tangential Flow Filtration] The Application of Tangential Flow Filtration Cassettes...

[Four-Piston Diaphragm Pumps] What is a Four-Piston Diaphragm Pump? How Does a Four-Piston Diaphragm Pump Work? What Are the Key Advantages of Four-Piston Diaphragm Pumps?...

[Photobioreactor] Photobioreactors are specialized cultivation systems designed to grow photosynthetic microorganisms such as microalgae, cyanobacteria, and other photosynthetic cells under controlled environmental conditions. Lab-scale photobioreactor systems serve as...

[Fermenters] Optimizing Fermenters for Enhanced Production...

[Bioreactors] Biological Reactions in Bioreactors: Advanced Solutions for Efficient Fermentation...

[Tangential Flow Filtration] Tangential Flow Filtration (TFF) is a separation process widely used in various industries, especially in biopharmaceutical manufacturing, water treatment, and chemical processes....

[Small Spray Dryers] Learn the Basics of Small Spray Dryers...

[Fermenter] You can find the answer to the question about fermenter feed supplement……...