The advantages and disadvantages of different ways of heating and stirring stainless steel fermenters were mentioned in the previous article, and today we will move on to talk about its other features.

How to cool stainless steel fermenter

There are two ways to cool the stainless steel fermenter: one is natural cooling and the other is forced cooling. Natural cooling is to use the air around the fermenter to reduce the temperature inside the tank, and forced cooling is to use a mechanical pump to reduce the temperature inside the vessel, but both methods require an air-cooled cooler above the fermenter.

Sterilization of stainless steel fermenter

Stainless steel fermenter adopts ultra-high temperature sterilization to sterilize the material inside the vessel. In the sterilization process, the temperature of the material in the vessel will be raised to 300-500℃ in an instant, and last for about 5-10 minutes. During this period, the pressure inside the vessel will instantly drop to zero, and the microorganisms in the material will be killed by the high temperature. This prevents microorganisms from producing spores and toxins under high temperature conditions. The material after ultra-high temperature sterilization will not be contaminated by microorganisms and microbial spores when the tank is sealed, and the nutritional value of the food can be well preserved.

The liquid in the stainless steel fermenter needs to be filtered to ensure its quality. The filtered liquid enters the stainless steel fermenter for stirring, and after stirring, it is then pumped into the sterilizing vessel for sterilization, so that the liquid in the tank can achieve the desired sterilization effect.

Other ancillary equipment of stainless steel fermenter

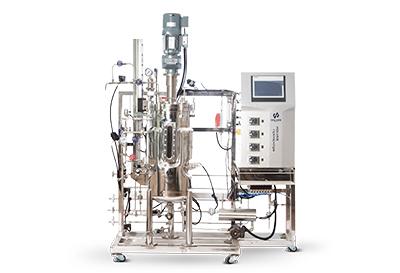

The ancillary equipment of stainless steel fermenter includes: electrical control cabinet, thermometer, stirring device, cooling device, etc. These ancillary facilities can effectively ensure the stable quality of the product.

More questions to solve?

More Questions

More Questions

[VIRTUAL Address] HOLVES Su310 intelligent stainless steel fermenter is a new generation of pilot and small-scale production equipment, integrating hardware innovation and intelligent control. In the pharmaceutical industry, stainless steel fermenters are crucial for produ...

[Ceramic Membrane Filtration] Ceramic membrane filtration is a physical separation process that uses ceramic materials with porous structures to separate particles, microorganisms, and dissolved substances from liquids....

[Tangential Flow Filtration] The Application of Tangential Flow Filtration Cassettes...

[Four-Piston Diaphragm Pumps] What is a Four-Piston Diaphragm Pump? How Does a Four-Piston Diaphragm Pump Work? What Are the Key Advantages of Four-Piston Diaphragm Pumps?...

[Photobioreactor] Photobioreactors are specialized cultivation systems designed to grow photosynthetic microorganisms such as microalgae, cyanobacteria, and other photosynthetic cells under controlled environmental conditions. Lab-scale photobioreactor systems serve as...

[Fermenters] Optimizing Fermenters for Enhanced Production...

[Bioreactors] Biological Reactions in Bioreactors: Advanced Solutions for Efficient Fermentation...

[Tangential Flow Filtration] Tangential Flow Filtration (TFF) is a separation process widely used in various industries, especially in biopharmaceutical manufacturing, water treatment, and chemical processes....

[Small Spray Dryers] Learn the Basics of Small Spray Dryers...

[Fermenter] You can find the answer to the question about fermenter feed supplement……...