Maintenance and upkeep of DO electrodes

# 1

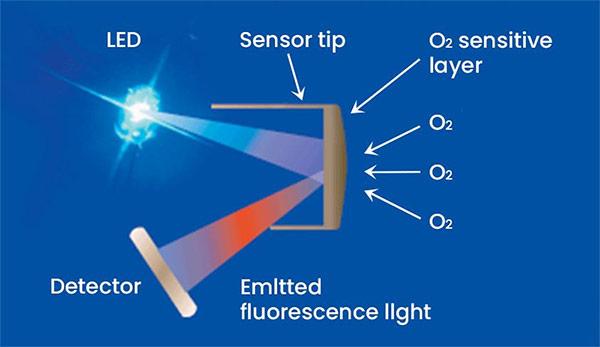

Basic types of DO electrodes

Note: The HOLVES bioreactor is standard equipped with METTLERTOLEDO InPro6800 series polariscopic DO electrodes. The following information is for this type of electrode only.

# 2

Preparation before use of DO electrode

- Electrode liquid

If the electrode signal is abnormal (such as long response time, increased current in anaerobic media, etc.) or the electrode appears "mechanical damage", it is necessary to replace the membrane or return to the original factory for maintenance.

- Procedure for changing the electrolyte:

- Pour off the residual electrolyte in the membrane, rinse the inside of the oxygen-dissolved membrane with deionized water, and then use absorbent paper to absorb the water marks after rinsing;

- Tilt the membrane, and the nozzle of the electrolyte bottle is vertically downward;

- Gently squeeze the electrolyte bottle, so that the electrolyte slowly flows into the membrane;

- The amount of electrolyte added is about 1/2;

- Confirm that there are no air bubbles inside the film, if there are air bubbles, flick the film body to remove air bubbles;

- Slowly rotate the membrane into the inner electrode, and then carefully tighten the stainless steel sleeve.

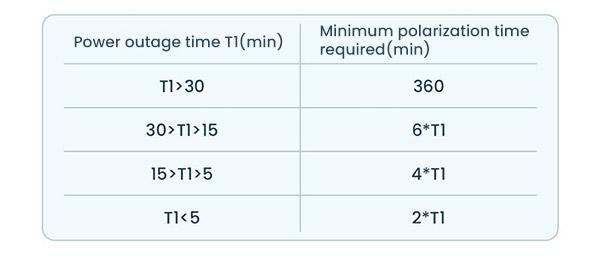

- Polarization of DO Electrode

- When the electrode is used for the first time, it should be polarized for more than 6 hours;

- Replace the membrane or electrolyte and polarize for more than 6 hours;

- When the transmitter is powered off or the electrode is disconnected from the cable, the minimum polarization time is shown in the table below.

# 3

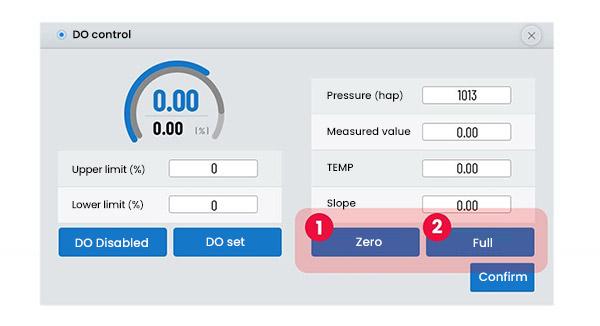

Calibration of DO electrode

- If air is used as the calibration medium, place the electrode in the air and wipe the water off the membrane. After the reading is stable, click "full scale confirmation";

- In the process of biochemical fermentation, the saturated medium is generally used as the calibration medium. After the actual elimination and before the inoculation, turn on the stirring to the maximum at a suitable temperature, and at the same time pass in the saturated air with the maximum ventilation for a certain period of time, and click "full confirmation" after the reading is stable. Calibration after a uniform aeration time is recommended to unify saturation across batches and fermenters.

# 4

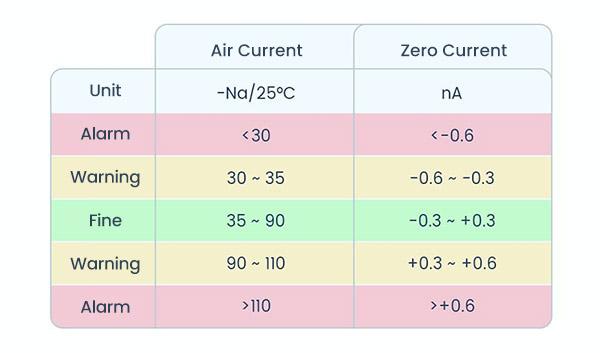

Performance test of DO electrode

If it is in the warning or alarm range, replace the electrolyte or membrane of the electrode and then re-calibrate. If it is still in the warning or alarm range after calibration, the electrode needs to be returned to the factory for repair.

If it is in the warning or alarm range, replace the electrolyte or membrane of the electrode and then re-calibrate. If it is still in the warning or alarm range after calibration, the electrode needs to be returned to the factory for repair.

# 5

The current value of the electrode in the air is abnormal

- The surface of the platinum cathode is covered with oxides

- The platinum cathode fails to contact the dissolved oxygen membrane

Check the DOF membrane, if there are excessive protrusions, so that the cathode cannot touch the membrane, the DOF must be replaced.

| Cause | Solution |

| Electrode polarization is insufficient | Confirm whether the polarization time matches |

| Electrodes are soiled | To clean the electrode, deionized water should be used instead of cleaning solution containing ethanol |

| Electrolyte aging | Replace the electrolyte |

| Membrane aging or damaged | Replace the membrane |

| Cable damaged | Replace the cable, the transmitter should display a very low and stable current value when the electrode is not connected |

| Transmitter damaged | Replace the transmitter |

# 6

Maintenance of DO electrode

More questions to solve?

More Questions

More Questions

[VIRTUAL Address] HOLVES Su310 intelligent stainless steel fermenter is a new generation of pilot and small-scale production equipment, integrating hardware innovation and intelligent control. In the pharmaceutical industry, stainless steel fermenters are crucial for produ...

[Ceramic Membrane Filtration] Ceramic membrane filtration is a physical separation process that uses ceramic materials with porous structures to separate particles, microorganisms, and dissolved substances from liquids....

[Tangential Flow Filtration] The Application of Tangential Flow Filtration Cassettes...

[Four-Piston Diaphragm Pumps] What is a Four-Piston Diaphragm Pump? How Does a Four-Piston Diaphragm Pump Work? What Are the Key Advantages of Four-Piston Diaphragm Pumps?...

[Photobioreactor] Photobioreactors are specialized cultivation systems designed to grow photosynthetic microorganisms such as microalgae, cyanobacteria, and other photosynthetic cells under controlled environmental conditions. Lab-scale photobioreactor systems serve as...

[Fermenters] Optimizing Fermenters for Enhanced Production...

[Bioreactors] Biological Reactions in Bioreactors: Advanced Solutions for Efficient Fermentation...

[Tangential Flow Filtration] Tangential Flow Filtration (TFF) is a separation process widely used in various industries, especially in biopharmaceutical manufacturing, water treatment, and chemical processes....

[Small Spray Dryers] Learn the Basics of Small Spray Dryers...

[Fermenter] You can find the answer to the question about fermenter feed supplement……...