Within the “Industry 4.0” landscape of biomanufacturing, the intelligent upgrade of fermenters is widely recognized as the segment with the greatest leverage effect. Internet of Things (IoT) technology deeply integrates sensors, communication, cloud computing, and artificial intelligence, transforming fermentation processes from experience-dependent models to data-centric intelligent systems. This evolution is progressively establishing fermentation systems capable of real-time sensing, online analysis, autonomous decision-making, and precise execution.

-

Value of IoT in Fermentation Operations

The fermentation process is a sophisticated biochemical reaction system where microorganisms respond to environmental changes at a rate measured in seconds, adjusting their metabolism and synthesizing products. It is highly sensitive to dynamic variations in environmental parameters such as temperature, pH, and dissolved oxygen.

Traditional monitoring methods, which rely on manual, scheduled sampling and offline analysis, suffer from significant lag. This delay often prevents timely process adjustments to match the actual physiological changes in microorganisms, leading to production issues like contamination and metabolic shifts. IoT technology achieves transparent and quantifiable fermentation management by establishing a fully digitalized mapping of the entire process.

Traditional monitoring methods, which rely on manual, scheduled sampling and offline analysis, suffer from significant lag. This delay often prevents timely process adjustments to match the actual physiological changes in microorganisms, leading to production issues like contamination and metabolic shifts. IoT technology achieves transparent and quantifiable fermentation management by establishing a fully digitalized mapping of the entire process.

1. Real-Time Monitoring

Modern intelligent fermenters are equipped with multiple high-precision sensors that continuously collect critical parameters such as internal temperature, pH, tank pressure, and exhaust gas composition. Integrated with powerful configuration software, the equipment provides operators with an intuitive, professional local monitoring and control interface, enabling centralized surveillance and control over equipment status, data acquisition, and parameter adjustment.

2. AI-Driven Risk Prediction

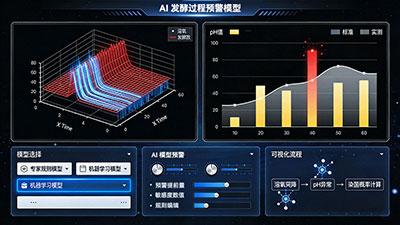

If real-time monitoring serves as the “sensory system” of the Internet of Things, then AI prediction acts as its “central nervous system.” Previously, Shanghai Jiao Tong University's “AI Engineer” system was applied to industrial fermentation. By integrating data streams from hundreds of sensors, it constructed a multi-scale digital twin model of the fermentation process. This system not only identifies early indicators of contamination risks in real time—such as abnormal dissolved oxygen fluctuations or sudden changes in CO2 release rates in exhaust gases—but also dynamically generates process optimization strategies through reinforcement learning algorithms. This enables a paradigm shift from reactive remediation to proactive prevention.

Modern intelligent fermenters are equipped with multiple high-precision sensors that continuously collect critical parameters such as internal temperature, pH, tank pressure, and exhaust gas composition. Integrated with powerful configuration software, the equipment provides operators with an intuitive, professional local monitoring and control interface, enabling centralized surveillance and control over equipment status, data acquisition, and parameter adjustment.

2. AI-Driven Risk Prediction

If real-time monitoring serves as the “sensory system” of the Internet of Things, then AI prediction acts as its “central nervous system.” Previously, Shanghai Jiao Tong University's “AI Engineer” system was applied to industrial fermentation. By integrating data streams from hundreds of sensors, it constructed a multi-scale digital twin model of the fermentation process. This system not only identifies early indicators of contamination risks in real time—such as abnormal dissolved oxygen fluctuations or sudden changes in CO2 release rates in exhaust gases—but also dynamically generates process optimization strategies through reinforcement learning algorithms. This enables a paradigm shift from reactive remediation to proactive prevention.

*News Source: CCTV News App

3. Remote Control

Cloud-based remote monitoring systems overcome geographical constraints in fermentation processes. Centralized management of fermenters is achieved through multiple terminals (PC/tablet/mobile phone). Operators can monitor fermentation conditions and equipment status in real time, enabling prompt adjustments upon detecting anomalies to prevent production losses from delayed responses. During exceptional periods like the COVID-19 pandemic, a biopharmaceutical company utilized this technology to achieve unmanned continuous production across provincial production bases, avoiding production disruptions caused by restricted personnel movement.

Cloud-based remote monitoring systems overcome geographical constraints in fermentation processes. Centralized management of fermenters is achieved through multiple terminals (PC/tablet/mobile phone). Operators can monitor fermentation conditions and equipment status in real time, enabling prompt adjustments upon detecting anomalies to prevent production losses from delayed responses. During exceptional periods like the COVID-19 pandemic, a biopharmaceutical company utilized this technology to achieve unmanned continuous production across provincial production bases, avoiding production disruptions caused by restricted personnel movement.

-

Challenges of IoT Technology in Fermentation

Although IoT technology has opened new horizons for the fermentation industry, its implementation still faces numerous technical challenges. These bottlenecks represent both obstacles that must be overcome for current industrial upgrades and the direction for future technological development.

1. Sensor Reliability Bottlenecks

The high-temperature, high-pressure, and highly acidic/alkaline environment inside fermentors imposes extreme operational demands on sensors. Current issues such as pH electrode drift and membrane contamination risks in dissolved oxygen sensors remain unresolved, leading to diminished data reliability during long-term operation. Furthermore, breakthroughs are still needed for online biosensors suitable for high-density fermentation systems (e.g., metabolite concentration probes), with key parameters still reliant on offline analysis.

1. Sensor Reliability Bottlenecks

The high-temperature, high-pressure, and highly acidic/alkaline environment inside fermentors imposes extreme operational demands on sensors. Current issues such as pH electrode drift and membrane contamination risks in dissolved oxygen sensors remain unresolved, leading to diminished data reliability during long-term operation. Furthermore, breakthroughs are still needed for online biosensors suitable for high-density fermentation systems (e.g., metabolite concentration probes), with key parameters still reliant on offline analysis.

2. Data Integration and Analytical Complexity

Effectively integrating multi-source data remains a core challenge. Protocol differences among devices from various manufacturers complicate system integration, while the inherent variability of fermentation processes renders traditional control models inadequate. More critically, the intrinsic batch-to-batch variability of biological processes demands AI models with continuous adaptive capabilities, imposing heightened requirements on algorithmic architecture design.

3. The Looming Threat of Cyber security

While cloud-edge collaboration architectures enhance operational efficiency, they also expand the attack surface. A documented case involved a fermentation enterprise where control system vulnerabilities led to malicious tampering of production parameters, resulting in the scrapping of an entire batch of products. Consequently, establishing a multi-layered security framework encompassing device authentication, encrypted data transmission, and access control has become an essential prerequisite for intelligent transformation.

Effectively integrating multi-source data remains a core challenge. Protocol differences among devices from various manufacturers complicate system integration, while the inherent variability of fermentation processes renders traditional control models inadequate. More critically, the intrinsic batch-to-batch variability of biological processes demands AI models with continuous adaptive capabilities, imposing heightened requirements on algorithmic architecture design.

3. The Looming Threat of Cyber security

While cloud-edge collaboration architectures enhance operational efficiency, they also expand the attack surface. A documented case involved a fermentation enterprise where control system vulnerabilities led to malicious tampering of production parameters, resulting in the scrapping of an entire batch of products. Consequently, establishing a multi-layered security framework encompassing device authentication, encrypted data transmission, and access control has become an essential prerequisite for intelligent transformation.

-

Intelligent Fermentation Upgrade

Currently, the intelligent evolution of fermentation equipment is shifting from the mere presence of data to how data creates value. Taking the Su310 series as an example, HOLVES has uniformly deployed the third-generation HF-Control v3.0 holographic intelligent control system across its entire product line. Through continuous product iteration, HOLVES has demonstrated a clear direction toward digital and networked transformation.

The current fermentation process still faces challenges where critical biological parameters—such as cell density and specific metabolite levels—rely on offline detection, leading to lag in process control. HOLVES may collaborate with sensor manufacturers to integrate advanced technologies like spectral analysis and multi-source data calibration. This would enable users to monitor cell density or key metabolite concentration changes in real time, much like tracking temperature data. Concurrently, standardizing the deployment of sensor self-diagnostic and self-calibration capabilities will establish a highly reliable, full-lifecycle data acquisition infrastructure.

For data applications, more specialized intelligent software for fermentation processes can be developed, offering visualization tools while also featuring standard AI model interfaces.

For data applications, more specialized intelligent software for fermentation processes can be developed, offering visualization tools while also featuring standard AI model interfaces.

*The image depicts an AI-generated fermentation warning model. For reference only.

The value of IoT technology ultimately lies in enhancing customer efficiency. This may also give rise to new service models, such as offering value-added services like predictive maintenance and process optimization subscriptions. These shift the relationship with users from a single product transaction to a deeper, long-term value symbiosis.

In summary, the deep integration of IoT and fermentation technology represents not merely a technological upgrade but a progressive reshaping of the entire industrial value chain. By establishing a new business architecture centered on the four pillars of “intelligent sensing, open platforms, collaborative networks, and value-added services,” relevant enterprises are poised to evolve from equipment manufacturers into enablers of intelligent transformation in biomanufacturing, collectively advancing progress in the era of Industry 4.0.

In summary, the deep integration of IoT and fermentation technology represents not merely a technological upgrade but a progressive reshaping of the entire industrial value chain. By establishing a new business architecture centered on the four pillars of “intelligent sensing, open platforms, collaborative networks, and value-added services,” relevant enterprises are poised to evolve from equipment manufacturers into enablers of intelligent transformation in biomanufacturing, collectively advancing progress in the era of Industry 4.0.