If we compare a fermenter to a city, then “zero contamination” is the only club in the city that is not open to the public—everyone knows about it, but tickets are extremely difficult to obtain. HOLVES' article is an invitation to everyone: reducing contamination to zero is not about performing sterilization multiple times, but about making the fermenter itself incapable of being contaminated.

-

Contamination sources: 90% of contamination comes from these three things

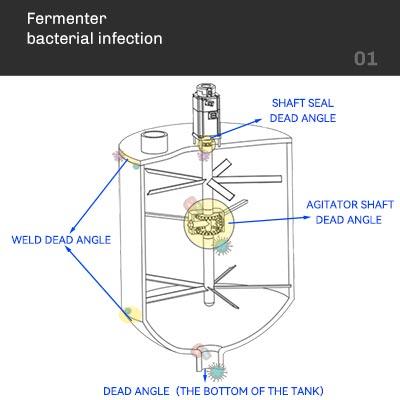

During fermenter operation, the contamination path appears to be hidden, but it is actually traceable.

1. Seal failure

Some traditional fermenter seals are prone to micro-leaks due to frequent opening and closing and long-term high-speed operation vibrations, which can become hidden pathways for contamination. When the fermenter cools down, negative pressure is formed, and outside air carrying contaminants can flow back through valve gaps and flange joints. Research shows that shaft seal contamination often occurs during the middle to late stages of equipment operation, and the root cause is usually seal wear that renders the barrier ineffective.

1. Seal failure

Some traditional fermenter seals are prone to micro-leaks due to frequent opening and closing and long-term high-speed operation vibrations, which can become hidden pathways for contamination. When the fermenter cools down, negative pressure is formed, and outside air carrying contaminants can flow back through valve gaps and flange joints. Research shows that shaft seal contamination often occurs during the middle to late stages of equipment operation, and the root cause is usually seal wear that renders the barrier ineffective.

2. Dead corner inside the vessel

Welded joints inside the vessel, stirrer shaft brackets, thermometer sleeves, and other parts are prone to accumulating solid culture medium, forming a biofilm shelter. If Bacillus subtilis hides in a 0.2 mm weld defect, it takes 30 minutes of continuous exposure to 134°C to kill it, which far exceeds the conventional SIP sterilization conditions.

3. Air filter

Air filters experience hydrophobicity degradation and filter core condensation in high-temperature, high-humidity environments, causing a sharp decline in interception efficiency and allowing external bacteria spores to enter unimpeded with the airflow.

Welded joints inside the vessel, stirrer shaft brackets, thermometer sleeves, and other parts are prone to accumulating solid culture medium, forming a biofilm shelter. If Bacillus subtilis hides in a 0.2 mm weld defect, it takes 30 minutes of continuous exposure to 134°C to kill it, which far exceeds the conventional SIP sterilization conditions.

3. Air filter

Air filters experience hydrophobicity degradation and filter core condensation in high-temperature, high-humidity environments, causing a sharp decline in interception efficiency and allowing external bacteria spores to enter unimpeded with the airflow.

-

Aseptic design of fermenters

“The best way to prevent contamination is to make operators forget that the sterilization button even exists.” The sterilization process for stainless steel fermenters can be achieved through the intelligent design of a fully automatic one-button sterilization program.

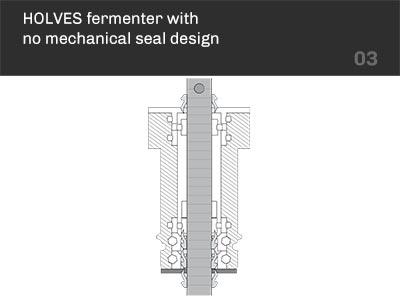

No mechanical seals, no leakage risk: HOLVES Laboratory glass fermenters abandon traditional sealing structures that are prone to leakage, eliminating the risk of contamination caused by seal wear and aging at the source. This design not only improves equipment reliability but also reduces maintenance costs.

High-quality materials, corrosion-resistant and durable: Made of high-quality 316L stainless steel, it has excellent corrosion resistance and biocompatibility, with a smooth surface that is easy to clean. It can effectively resist the erosion of various microorganisms and extend the service life of the equipment.

In addition, HOLVES stainless steel fermenters have sterile sampling valve interfaces reserved on the side walls of the tank, which can be plugged into five-hole samplers for plug-and-play use, enabling zero-exposure sampling and ensuring the accuracy of experiments and product safety.(Click on the image below to learn more.)

In addition, HOLVES stainless steel fermenters have sterile sampling valve interfaces reserved on the side walls of the tank, which can be plugged into five-hole samplers for plug-and-play use, enabling zero-exposure sampling and ensuring the accuracy of experiments and product safety.(Click on the image below to learn more.)

Intelligent control system, precise monitoring: Equipped with an advanced intelligent control system, it can monitor and regulate various parameters in the fermentation process in real time, such as temperature, pH value, dissolved oxygen, etc., to ensure the stability and consistency of the fermentation process.

-

The science behind sterile design

The aseptic design of HOLVES fermenters is based on a series of scientific principles:

Hydromechanics: The fluid flow path inside the vessel has been optimized through the design of vessel structures such as paddles and baffles, reducing dead corners and turbulence and lowering the possibility of bacterial growth.

Principles of Microbiology: Understand the growth habits and transmission routes of contaminants, and design targeted protective measures to effectively inhibit the growth and reproduction of contaminants.

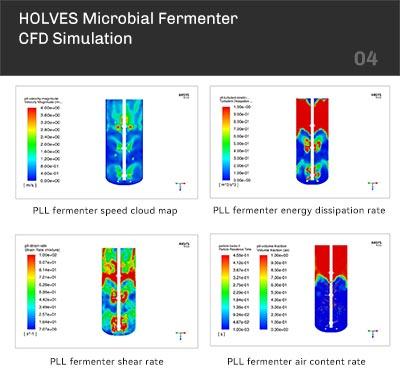

HOLVES employs advanced computational fluid dynamics (CFD) simulation technology to conduct high-precision simulation analyses of fluid flow patterns, temperature distributions, and other parameters within fermentation tanks. By constructing complex three-dimensional models, we simulate fluid dynamic behavior under various agitator configurations, baffle layouts, and operational parameters.

Hydromechanics: The fluid flow path inside the vessel has been optimized through the design of vessel structures such as paddles and baffles, reducing dead corners and turbulence and lowering the possibility of bacterial growth.

Principles of Microbiology: Understand the growth habits and transmission routes of contaminants, and design targeted protective measures to effectively inhibit the growth and reproduction of contaminants.

HOLVES employs advanced computational fluid dynamics (CFD) simulation technology to conduct high-precision simulation analyses of fluid flow patterns, temperature distributions, and other parameters within fermentation tanks. By constructing complex three-dimensional models, we simulate fluid dynamic behavior under various agitator configurations, baffle layouts, and operational parameters.

Based on the simulation results, HOLVES engineers were able to precisely optimize the internal structure of the tank and the sterilization process parameters to ensure uniform and thorough thermal coverage of the culture medium and tank surface, effectively eliminating microscopic sterilization blind spots that are difficult to detect in conventional designs, and minimizing the risk of contamination from a fluid dynamics perspective. This research provides a strong theoretical basis and optimization direction for “zero contamination” design.

In actual verification, the aseptic performance of HOLVES fermenters has been fully supported by data. Through rigorous aseptic testing and systematic comparative experimental analysis, the results show that after adopting HOLVES fermenters, the contamination rate has been significantly reduced by more than 90%. Its optimized aseptic design and strict production process control capabilities enable the contamination rate to approach zero. This has directly led to a significant improvement in product quality and a substantial optimization of production efficiency. In various production environments, the sterile design of the HOLVES fermenter has been proven to effectively ensure the consistency and stability of product quality.

Whether in laboratory research or industrial production, HOLVES fermenters provide users with a reliable and efficient sterile fermentation platform, helping companies achieve high-quality production.

In actual verification, the aseptic performance of HOLVES fermenters has been fully supported by data. Through rigorous aseptic testing and systematic comparative experimental analysis, the results show that after adopting HOLVES fermenters, the contamination rate has been significantly reduced by more than 90%. Its optimized aseptic design and strict production process control capabilities enable the contamination rate to approach zero. This has directly led to a significant improvement in product quality and a substantial optimization of production efficiency. In various production environments, the sterile design of the HOLVES fermenter has been proven to effectively ensure the consistency and stability of product quality.

Whether in laboratory research or industrial production, HOLVES fermenters provide users with a reliable and efficient sterile fermentation platform, helping companies achieve high-quality production.