The global wine industry produces approximately 8 million tons of grape pomace annually, with 70% of it being landfilled or incinerated. However, these waste materials also hold significant value, such as proanthocyanidins in grape seeds and anthocyanins and resveratrol in grape skins. Grape seed extract is a novel, highly effective natural antioxidant substance derived from grape seeds. The polyphenolic compounds found in grape seeds primarily include catechins and proanthocyanidins. Catechin compounds, such as catechin, epicatechin, and their gallate esters, are the main monomers in grape seeds and also serve as the building blocks for proanthocyanidin oligomers and polymers.

They are currently the most potent active substances discovered in nature for their antioxidant and free radical scavenging properties. Research indicates that grape seed extract contains high levels of proanthocyanidins, with antioxidant capacity 20 times that of vitamin C and 50 times that of vitamin E. How can we efficiently extract the desired substances from grape seeds and grape skins?

They are currently the most potent active substances discovered in nature for their antioxidant and free radical scavenging properties. Research indicates that grape seed extract contains high levels of proanthocyanidins, with antioxidant capacity 20 times that of vitamin C and 50 times that of vitamin E. How can we efficiently extract the desired substances from grape seeds and grape skins?

Application of ceramic membrane filtration technology in grape seeds and grape skins

Ceramic membrane filtration is a precision separation technology based on molecular size. Its core is a porous structure made of inorganic materials such as aluminum oxide and zirconium oxide, which achieves selective screening of different components through nanometer-sized pores. When processing grape by-products:

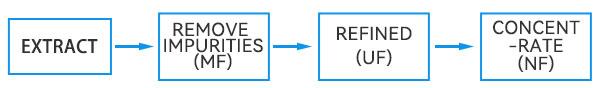

1. For grape seeds, we can first filter the grape seed extract through a ceramic membrane to remove broken shells and gelatinous substances using microfiltration(MF). Then, we use ultrafiltration(UF) membranes to retain large-molecule proteins, followed by nanofiltration(NF) for separation and concentration. Compared to traditional processes, membrane separation technology is simple, efficient, energy-efficient, and produces high-quality products, making it suitable for large-scale industrial applications.

2. For grape skins, we need an additional step of pretreatment to remove the mucilage in the skins to prevent membrane contamination. Then, low-temperature ultrafiltration can be used to separate anthocyanins and tannic acid, followed by nanofiltration to adsorb resveratrol.

1. For grape seeds, we can first filter the grape seed extract through a ceramic membrane to remove broken shells and gelatinous substances using microfiltration(MF). Then, we use ultrafiltration(UF) membranes to retain large-molecule proteins, followed by nanofiltration(NF) for separation and concentration. Compared to traditional processes, membrane separation technology is simple, efficient, energy-efficient, and produces high-quality products, making it suitable for large-scale industrial applications.

2. For grape skins, we need an additional step of pretreatment to remove the mucilage in the skins to prevent membrane contamination. Then, low-temperature ultrafiltration can be used to separate anthocyanins and tannic acid, followed by nanofiltration to adsorb resveratrol.

Efficiency improvement: From time-consuming processes to continuous production

Traditional extraction faces multiple efficiency challenges:

The alcohol precipitation process requires 8-12 hours of sedimentation.

The centrifugal impurity removal process repeatedly interrupts production flow.

Ceramic membrane technology has made a qualitative leap forward through three-stage integration:

The alcohol precipitation process requires 8-12 hours of sedimentation.

The centrifugal impurity removal process repeatedly interrupts production flow.

Ceramic membrane technology has made a qualitative leap forward through three-stage integration:

1. Economic benefits: The ceramic membrane filtration process improves the yield and purity of proanthocyanidins in grape seeds.

2. Environmental benefits: Ceramic membrane filtration reduces waste emissions and saves energy and reduces consumption.

The use of NF membrane and ceramic membrane filtration technology for extracting proanthocyanidins from grape seeds has the following advantages:

1. Improve the storage stability of anthocyanin products, making them less susceptible to temperature, light, and other conditions that can reduce their coloring properties.

2. Molecular-level screening removes large molecular impurities such as plant fibers and proteins, resulting in a product with high clarity and purity.

3. Concentration at normal temperature reduces energy consumption, removes part of the water and ash, reduces the volume of thermal concentration, shortens the thermal concentration time, and reduces the loss of active ingredients in the product.

4. Membrane filtration is highly automated, safe, and reliable, effectively reducing labor intensity. The membrane filtration process is carried out in a closed container, achieving clean production.

Ceramic membrane filtration technology has completely transformed the utilization model of grape by-products with its precise screening, gentle and efficient, and circular low-carbon characteristics. It not only converts wine-making waste into high-value products such as antioxidants and natural pigments, but also promotes the transformation of the food industry towards “zero waste.”

The application prospects for ceramic membrane filtration systems are also extremely promising. In the future, ceramic membrane filtration systems will evolve toward greater intelligence. By integrating advanced sensors and control systems, real-time monitoring and automatic adjustment of the filtration process can be achieved, thereby enhancing filtration efficiency and the stability of product quality. As a bunch of grapes undergoes its journey from fruit to wine, and then from pomace to essence, this technology is setting a benchmark for resource regeneration—demonstrating that technology and nature can indeed coexist harmoniously.

2. Environmental benefits: Ceramic membrane filtration reduces waste emissions and saves energy and reduces consumption.

The use of NF membrane and ceramic membrane filtration technology for extracting proanthocyanidins from grape seeds has the following advantages:

1. Improve the storage stability of anthocyanin products, making them less susceptible to temperature, light, and other conditions that can reduce their coloring properties.

2. Molecular-level screening removes large molecular impurities such as plant fibers and proteins, resulting in a product with high clarity and purity.

3. Concentration at normal temperature reduces energy consumption, removes part of the water and ash, reduces the volume of thermal concentration, shortens the thermal concentration time, and reduces the loss of active ingredients in the product.

4. Membrane filtration is highly automated, safe, and reliable, effectively reducing labor intensity. The membrane filtration process is carried out in a closed container, achieving clean production.

Ceramic membrane filtration technology has completely transformed the utilization model of grape by-products with its precise screening, gentle and efficient, and circular low-carbon characteristics. It not only converts wine-making waste into high-value products such as antioxidants and natural pigments, but also promotes the transformation of the food industry towards “zero waste.”

The application prospects for ceramic membrane filtration systems are also extremely promising. In the future, ceramic membrane filtration systems will evolve toward greater intelligence. By integrating advanced sensors and control systems, real-time monitoring and automatic adjustment of the filtration process can be achieved, thereby enhancing filtration efficiency and the stability of product quality. As a bunch of grapes undergoes its journey from fruit to wine, and then from pomace to essence, this technology is setting a benchmark for resource regeneration—demonstrating that technology and nature can indeed coexist harmoniously.