In the fermenter, precise regulation determines yeast cell growth, metabolism and yield. Any spot of shear, dissolved oxygen gradient or mixing dead space can break the chain and product yields collapse.

Dependence of yeast cells on fermenters

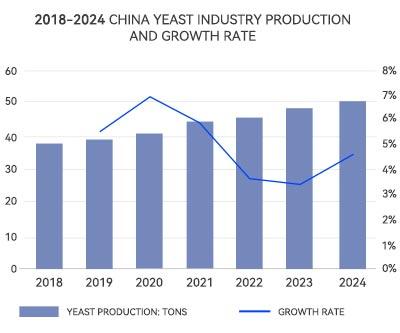

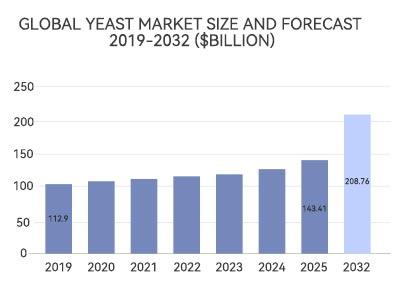

With more than 50 million yeast-involved end-product products (beer, bread, recombinant proteins, biofuels, etc.) globally each year, fermenters are no longer just containers, but sophisticated ecosystems that incorporate genetic engineering and metabolic regulation. In this artificial environment, yeast cells transform substances with a thousand times greater efficiency than nature, creating products ranging from food ingredients to biofuels.

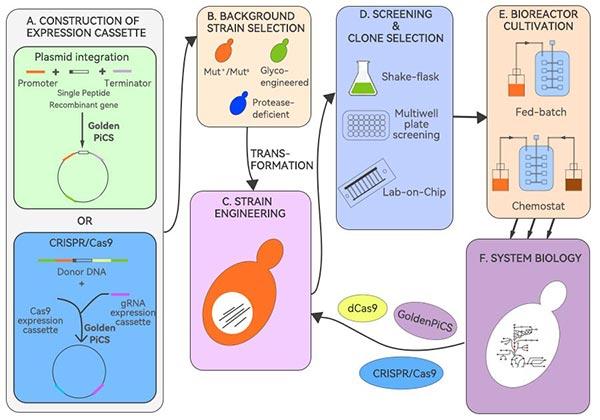

Pichia pastoris is commonly used for recombinant protein expression (e.g., adjuvants in vaccines) because of its genetic stability of exogenous genes, fast cell growth rate, high product expression efficiency, and independence from endotoxin and phage, and its ability to efficiently transcribe and translate proteins and accurately accomplish protein processing modifications. However, these applications place harsh demands on the fermenter, which is yeast fermentation relies on constant temperature, pH, and a homogeneous nutrient environment. A rudimentary culture vessel can trigger uneven cell growth, product inhibition, or batch failure, leading to significant economic losses.

Meanwhile, the application of yeast has expanded to pet food, for example, by extracting the target protein gene from chicken skeletal muscle cells and implanting it in modified yeast. The microorganisms carrying the animal protein gene are then fed into a closed fermenter, where they work together with sugars, salts and minerals. A few days later, an animal protein powder with a purity of more than 98% is created in the tank, a method that not only eliminates the need to slaughter animals, but also yields a protein that is identical to that of natural meat.

Although yeast is required in different industries, the physiological state and product targets of yeast strains have very different requirements, which directly determine the precision standards of the operating parameters of fermentors. From tiny seed tanks to huge industrialized production tanks, each scale-up is never a simple volume doubling, but requires methodological scaling up with a combination of factors.

It is necessary to ensure that the linear amplification error of key parameters, such as shear force, mass transfer rate, and dissolved oxygen level, is minimized, and that the optimal fermentation process parameters are confirmed step by step in conjunction with the optimization of fermentation basal conditions and the optimization of replenishment strategy, in order to maintain the optimal metabolic environment of yeast cells.

Although yeast is required in different industries, the physiological state and product targets of yeast strains have very different requirements, which directly determine the precision standards of the operating parameters of fermentors. From tiny seed tanks to huge industrialized production tanks, each scale-up is never a simple volume doubling, but requires methodological scaling up with a combination of factors.

It is necessary to ensure that the linear amplification error of key parameters, such as shear force, mass transfer rate, and dissolved oxygen level, is minimized, and that the optimal fermentation process parameters are confirmed step by step in conjunction with the optimization of fermentation basal conditions and the optimization of replenishment strategy, in order to maintain the optimal metabolic environment of yeast cells.

Design of fermenter stirring system

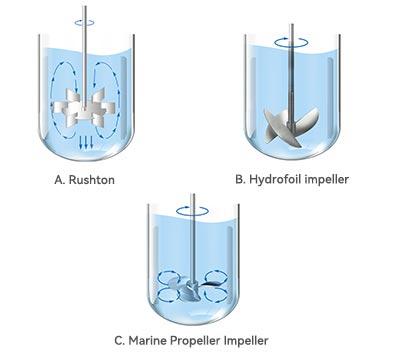

Fermentor stirring system is not a simple mechanical rotation, its role is to overcome the fluid resistance, the vessel will be uniformly mixed culture fluid, increase the effective contact area of the dispersed phase, reduce the dispersed phase around the liquid film resistance as well as increase the relative speed to improve the rate of heat transfer, etc., to create a suitable micro-environment for fermentation.

Sedimentation or aggregation of yeast cells in the fermentation broth can lead to localized nutrient deprivation, accumulation of metabolic wastes and the formation of temperature/pH gradients. Selecting the appropriate paddle according to the process requirements and finding a specific rotational speed corresponding to it allows for optimal balance between mixing effect and shear force generated. For example, in the case of recombinant protein production by Brettanomyces cerevisiae, the Rushton mixing paddle generates high shear, but its unique flat blade design creates an upper and lower double-circulation flow field, which is particularly suitable for the cultivation of aerobic yeasts. The H-Mix® seal-less design developed by HOLVES Fermenter solves the risk of leakage and bacterial contamination associated with traditional mechanical seals, allowing the mixing system to maintain sterility while maintaining a high rotational speed.

Sedimentation or aggregation of yeast cells in the fermentation broth can lead to localized nutrient deprivation, accumulation of metabolic wastes and the formation of temperature/pH gradients. Selecting the appropriate paddle according to the process requirements and finding a specific rotational speed corresponding to it allows for optimal balance between mixing effect and shear force generated. For example, in the case of recombinant protein production by Brettanomyces cerevisiae, the Rushton mixing paddle generates high shear, but its unique flat blade design creates an upper and lower double-circulation flow field, which is particularly suitable for the cultivation of aerobic yeasts. The H-Mix® seal-less design developed by HOLVES Fermenter solves the risk of leakage and bacterial contamination associated with traditional mechanical seals, allowing the mixing system to maintain sterility while maintaining a high rotational speed.

How to conquer high viscosity products?

Mixing challenges increase steeply when the fermentation system involves highly viscous products. For example, in the case of high-density fermentation using Saccharomyces cerevisiae for the production of gel polysaccharides, the apparent viscosity of the fermentation broth in the tank continues to rise as its content continues to increase, and the gas-liquid mass transfer and mixing of the material deteriorate, with the dissolved oxygen concentration rapidly decreasing or even dropping to zero during the latter part of the fermentation period, and with large fluctuations in pH and temperature, which can have an extremely negative impact on the polysaccharide synthesis process.

Traditional mixing is easy to form a “cave effect”, that is, the paddles only drive a limited number of surrounding fluid rotation, most of the tank is in a relatively static state, which not only results in a dead zone of mixing, but also seriously impedes the transfer of dissolved oxygen to the yeast cells. HOLVES fermenter will be based on the actual working conditions of customers, using different types of paddle combination, retaining the vortex mixing paddle excellent oxygen transfer effect, but also increase the mixed flow type paddle, to avoid cell damage at the same time, but also in the high viscosity of the material with better mixing effect.

Traditional mixing is easy to form a “cave effect”, that is, the paddles only drive a limited number of surrounding fluid rotation, most of the tank is in a relatively static state, which not only results in a dead zone of mixing, but also seriously impedes the transfer of dissolved oxygen to the yeast cells. HOLVES fermenter will be based on the actual working conditions of customers, using different types of paddle combination, retaining the vortex mixing paddle excellent oxygen transfer effect, but also increase the mixed flow type paddle, to avoid cell damage at the same time, but also in the high viscosity of the material with better mixing effect.

About DO

Dissolved oxygen (DO) is at the core of yeast fermentation: it directly affects yeast growth rate, alcohol yield and metabolism. Yeast are typically facultative anaerobic microorganisms whose metabolic pathways shift radically with ambient dissolved oxygen levels:

Enough DO conditions: Yeast proliferates rapidly through efficient aerobic respiration pathway, biomass accumulates dramatically, and ethanol production is suppressed.

Low/No DO conditions: Yeast initiate anaerobic fermentation, sacrificing growth efficiency for survival and converting sugars primarily to ethanol.

Critical DO fluctuations: Frequent crossing of aerobic/anaerobic thresholds triggers oscillations in yeast metabolism, leading to an abnormal accumulation of by-products (e.g., heterohydric alcohols, acids), which can significantly impair the flavor and purity of the final product.

The HOLVES intelligent control system captures the fluctuation of dissolved oxygen in real time through the DO electrode, and automatically adjusts the aeration volume, stirring speed, tank pressure parameters or replenishment according to the value of the dissolved oxygen setting, to ensure that the dissolved oxygen conditions required by the yeast cells at different growth stages. The equipment is also equipped with sequential control, which can automatically modify the main parameters such as dissolved oxygen, temperature, pH, etc. according to the customized time period, or carry out automatic flow and replenishment to realize the induction conditions.

Enough DO conditions: Yeast proliferates rapidly through efficient aerobic respiration pathway, biomass accumulates dramatically, and ethanol production is suppressed.

Low/No DO conditions: Yeast initiate anaerobic fermentation, sacrificing growth efficiency for survival and converting sugars primarily to ethanol.

Critical DO fluctuations: Frequent crossing of aerobic/anaerobic thresholds triggers oscillations in yeast metabolism, leading to an abnormal accumulation of by-products (e.g., heterohydric alcohols, acids), which can significantly impair the flavor and purity of the final product.

The HOLVES intelligent control system captures the fluctuation of dissolved oxygen in real time through the DO electrode, and automatically adjusts the aeration volume, stirring speed, tank pressure parameters or replenishment according to the value of the dissolved oxygen setting, to ensure that the dissolved oxygen conditions required by the yeast cells at different growth stages. The equipment is also equipped with sequential control, which can automatically modify the main parameters such as dissolved oxygen, temperature, pH, etc. according to the customized time period, or carry out automatic flow and replenishment to realize the induction conditions.