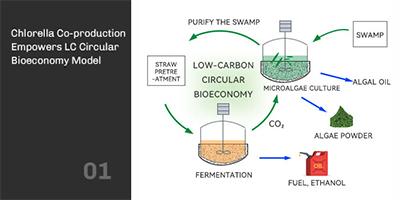

Against the backdrop of the global energy and climate governance system, the traditional economic model is accelerating its transition toward a sustainable development paradigm. This global trend resonates with China's “dual carbon” (carbon peak and carbon neutrality) strategic goals, compelling high-carbon industries such as steel, metallurgy, and silicomanganese alloys to seek low-cost, high-efficiency emission reduction pathways. In particular, the refined monitoring and resource utilization of fermentation process tail gases are emerging as a critical link connecting carbon sources with high-value-added products.

As the core reactor in this system, the fermentor has evolved from a traditional bioproduct manufacturing device into a miniature cellular factory that recycles exhaust gases, providing a practical technological solution for achieving the dual carbon goals.

As the core reactor in this system, the fermentor has evolved from a traditional bioproduct manufacturing device into a miniature cellular factory that recycles exhaust gases, providing a practical technological solution for achieving the dual carbon goals.

-

The New Energy Potential of Biomanufacturing

Breakthroughs in biotechnology, particularly advances in synthetic biology and metabolic engineering, enable microbial cell factories to achieve targeted conversion of carbon-containing gases, transforming traditional industrial exhaust into liquid fuels and chemicals. In typical fermentation processes, the direct emission of high-purity CO₂from the exhaust gas represents a waste of carbon resources.

Modern fermentation systems integrate gas recovery modules, reducing direct carbon emissions per cubic meter of fermentation broth by 60-80%. Certain advanced strains achieve conversion efficiencies of up to 85% of the theoretical value for carbon monoxide, transforming industrial waste gases into liquid fuels such as ethanol and butanol. This dual objective enhances energy density while optimizing transportation costs. Consequently, monitoring and controlling exhaust gas composition has become critical for optimizing the fermentation process.

-

Effects of Exhaust Gas Components on the Fermentation Process

Whether in food, beverage, pharmaceutical, or biofuel production, carbon dioxide (CO₂) and oxygen (O₂) concentrations in fermentation exhaust gases are critical parameters. Their equilibrium directly impacts fermentation success, making real-time monitoring of these gases essential for process optimization.

The Impact of Carbon Dioxide (CO₂)

Positive effects: Maintaining appropriate CO₂ levels helps stabilize the pH of the fermentation broth, creating a stable growth environment for microorganisms. Additionally, in certain specific fermentations, a certain amount of CO₂ serves as a substrate required for microorganisms to synthesize target products.

Negative Effects: When CO₂ accumulation exceeds critical levels, its detrimental effects become pronounced. The most direct consequence is that high CO₂ concentrations reduce dissolved oxygen in the fermentation broth, inhibiting aerobic microorganisms and potentially causing direct cellular toxicity, thereby increasing environmental burden.

The Impact of oxygen (O₂)

Positive Effects: O₂ is essential for aerobic microorganisms to perform respiration, generating energy to sustain growth and anabolic processes. Providing ample, sterile oxygen via compressed air is fundamental to ensuring rapid microbial proliferation and successful cultivation.

Negative Effects: However, more O₂ is not necessarily better. Excessive O₂ triggers a series of oxidative reactions, altering microbial metabolic pathways, producing unwanted byproducts, and inhibiting certain anaerobic metabolic processes.

The Impact of Carbon Dioxide (CO₂)

Positive effects: Maintaining appropriate CO₂ levels helps stabilize the pH of the fermentation broth, creating a stable growth environment for microorganisms. Additionally, in certain specific fermentations, a certain amount of CO₂ serves as a substrate required for microorganisms to synthesize target products.

Negative Effects: When CO₂ accumulation exceeds critical levels, its detrimental effects become pronounced. The most direct consequence is that high CO₂ concentrations reduce dissolved oxygen in the fermentation broth, inhibiting aerobic microorganisms and potentially causing direct cellular toxicity, thereby increasing environmental burden.

The Impact of oxygen (O₂)

Positive Effects: O₂ is essential for aerobic microorganisms to perform respiration, generating energy to sustain growth and anabolic processes. Providing ample, sterile oxygen via compressed air is fundamental to ensuring rapid microbial proliferation and successful cultivation.

Negative Effects: However, more O₂ is not necessarily better. Excessive O₂ triggers a series of oxidative reactions, altering microbial metabolic pathways, producing unwanted byproducts, and inhibiting certain anaerobic metabolic processes.

-

Fermentation exhaust gas treatment and control system

To deal with the effects mentioned above and ensure sterile production, the exhaust gas control system of the fermentor requires meticulous design and control.

Basic Control and Sterility Assurance: During fermentation, sterile compressed air is fed into the vessel after passing through sterilizing filters to supply oxygen. The exhaust gas pipeline must undergo rigorous treatment. At laboratory or pilot scale, a common practice involves controlling exhaust gas discharge volume via a valve to maintain tank pressure, while directing the exhaust gas into an alkaline solution for simple disinfection and deodorization.

Basic Control and Sterility Assurance: During fermentation, sterile compressed air is fed into the vessel after passing through sterilizing filters to supply oxygen. The exhaust gas pipeline must undergo rigorous treatment. At laboratory or pilot scale, a common practice involves controlling exhaust gas discharge volume via a valve to maintain tank pressure, while directing the exhaust gas into an alkaline solution for simple disinfection and deodorization.

In large-scale industrial production, the systems are more complex and sophisticated, typically employing fully automated control systems to maintain stable vessel pressure. Another critical component is the filter (inlet air filter and exhaust gas filter), which undergoes online steam sterilization (SIP) alongside the fermentation tank. Its primary purpose is not only to trap microorganisms potentially present in the exhaust gas but, more importantly, to prevent contaminants from external air entering the fermentation tank through the exhaust pipe, thereby preventing contamination incidents. This serves as the lifeline for ensuring long-term sterile cultivation.

Process Monitoring and Optimization: During fermentation, exhaust gas composition serves as a critical indicator reflecting metabolic status. The exhaust gas analysis system integrated into HOLVES fermenters enables real-time monitoring and analysis of gas concentration changes in CO, CO₂, O₂, and other components. It calculates key parameters such as oxygen uptake rate (OUR) and carbon-dioxide escape rate (CER), thereby inferring microbial metabolic activity and substrate conversion efficiency. This provides data support for process optimization and carbon accounting while laying the foundation for further resource utilization of exhaust gases.

Process Monitoring and Optimization: During fermentation, exhaust gas composition serves as a critical indicator reflecting metabolic status. The exhaust gas analysis system integrated into HOLVES fermenters enables real-time monitoring and analysis of gas concentration changes in CO, CO₂, O₂, and other components. It calculates key parameters such as oxygen uptake rate (OUR) and carbon-dioxide escape rate (CER), thereby inferring microbial metabolic activity and substrate conversion efficiency. This provides data support for process optimization and carbon accounting while laying the foundation for further resource utilization of exhaust gases.

-

Deep Resource Recovery of Exhaust Gases

While ensuring process control, fermentation exhaust gas itself is also regarded as a resource. The core of achieving a circular economy lies in how to effectively utilize this resource.

1. Gas pretreatment: Fermentation exhaust gas is characterized by high temperature and high humidity. It must undergo pretreatment processes such as cooling and dehumidification, as well as membrane separation, to remove moisture and other components, thereby creating suitable conditions for subsequent utilization.

1. Gas pretreatment: Fermentation exhaust gas is characterized by high temperature and high humidity. It must undergo pretreatment processes such as cooling and dehumidification, as well as membrane separation, to remove moisture and other components, thereby creating suitable conditions for subsequent utilization.

2. Microbial Conversion: A deeper cycle occurs within the reactor itself, where pretreated gas is introduced into the vessel.

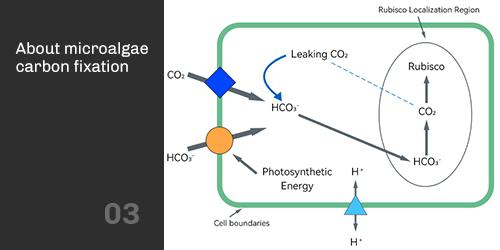

Microalgal Carbon Fixation: Organisms like chlorella and cyanobacteria utilize CO₂ from exhaust gases to synthesize lipids, polysaccharides, or proteins through photosynthesis;

Chemical Synthesis: Microorganisms such as Hydrogenococcus utilize hydrogen as an energy source to convert CO₂ into biodegradable PHA plastics;

Carbon Monoxide Utilization: Anaerobic bacteria like Clostridium yamani can utilize CO or synthesis gas to produce chemicals like ethanol and butanol.

Microalgal Carbon Fixation: Organisms like chlorella and cyanobacteria utilize CO₂ from exhaust gases to synthesize lipids, polysaccharides, or proteins through photosynthesis;

Chemical Synthesis: Microorganisms such as Hydrogenococcus utilize hydrogen as an energy source to convert CO₂ into biodegradable PHA plastics;

Carbon Monoxide Utilization: Anaerobic bacteria like Clostridium yamani can utilize CO or synthesis gas to produce chemicals like ethanol and butanol.

3. Product Separation and Gas Recirculation

Online Product Removal: Accumulation of products in fermentation broth inhibits microbial activity. To prevent feedback inhibition, continuous removal of products (e.g., ethanol) from the broth via gas stripping, membrane separation, or similar technologies avoids feedback inhibition and enhances production efficiency.

Targeted CO₂ Recovery: In industries like brewing, CO₂-rich exhaust gases are purified before recirculation or discharge. This yields industrial-grade or food-grade CO₂ for carbonated beverages, dry ice production, and other applications, enabling cross-industry resource recycling.

Exhaust Gas Recycling: Exhaust gases discharged from fermenter still contain significant amounts of unreacted CO/CO₂. By reintroducing these gases into the system via a recirculation compressor, the single-pass conversion rate of the carbon source is maximized.

Online Product Removal: Accumulation of products in fermentation broth inhibits microbial activity. To prevent feedback inhibition, continuous removal of products (e.g., ethanol) from the broth via gas stripping, membrane separation, or similar technologies avoids feedback inhibition and enhances production efficiency.

Targeted CO₂ Recovery: In industries like brewing, CO₂-rich exhaust gases are purified before recirculation or discharge. This yields industrial-grade or food-grade CO₂ for carbonated beverages, dry ice production, and other applications, enabling cross-industry resource recycling.

Exhaust Gas Recycling: Exhaust gases discharged from fermenter still contain significant amounts of unreacted CO/CO₂. By reintroducing these gases into the system via a recirculation compressor, the single-pass conversion rate of the carbon source is maximized.

Additionally, based on exhaust gas analysis data, the system intelligently adjusts gas recirculation ratios and make-up gas strategies to maximize carbon source utilization while preventing metabolic product accumulation and inhibition. The design of the HOLVES fermentor enables closed-loop operation for exhaust gas recovery and process control, further enhancing the system's economic efficiency and environmental performance.

Fermenter exhaust gas recovery technology extends far beyond end-of-pipe treatment. It has become a pivotal lever for enterprises to build core competitiveness and respond to the national “dual carbon” strategy in the era of carbon constraints. By transforming industrial burdens into assets, it constructs a more resilient and sustainable circular economy system. From global consensus to Chinese action, this represents not merely a technological pathway, but a profound practice of industrial civilization moving toward harmonious coexistence with the Earth's ecosystem.

Fermenter exhaust gas recovery technology extends far beyond end-of-pipe treatment. It has become a pivotal lever for enterprises to build core competitiveness and respond to the national “dual carbon” strategy in the era of carbon constraints. By transforming industrial burdens into assets, it constructs a more resilient and sustainable circular economy system. From global consensus to Chinese action, this represents not merely a technological pathway, but a profound practice of industrial civilization moving toward harmonious coexistence with the Earth's ecosystem.