In 2023, a Science Advances paper on the separation of vaccine nanoparticles generated a buzz: using an improved tangential flow filtration (TFF) system, researchers succeeded in increasing the recovery of Zika virus-like particles from 68% to 94%, while reducing host cell protein residues to below the detection limit. This breakthrough pushes the strategic value of TFF in the vaccine industry back into the spotlight - as global vaccine R&D enters a new battleground where nanoscale and complex components coexist, this technology, which was born in the 1970s, is reconfiguring the core logic of vaccine production through underlying innovations.

-

Critical aspects of vaccine production

1、Concentration of target fractions:

Purpose: To increase the concentration of the target by substantially reducing the volume of material containing the target antigen (e.g., viral particles, virus-like particles, recombinant proteins, nucleic acids, etc.) prior to or after the purification step.

Purpose: To increase the concentration of the target by substantially reducing the volume of material containing the target antigen (e.g., viral particles, virus-like particles, recombinant proteins, nucleic acids, etc.) prior to or after the purification step.

Applications:

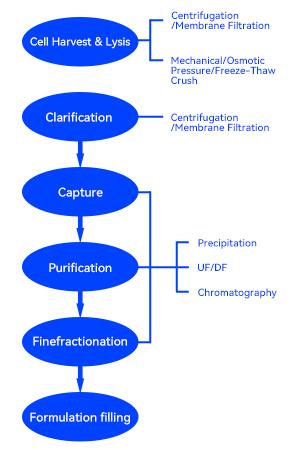

Downstream Clarification Concentration: After cell culture or fermentation, the target concentration in the initial clarification (e.g., deep filtration, centrifugation) is usually low and needs to be concentrated by TFF in order to reduce the sample volume and processing time of the subsequent chromatography columns.

Chromatographic eluent concentration: The eluent after chromatographic purification (e.g., ion exchange, molecular sieve, affinity chromatography) is usually large in volume and low in concentration, so TFF can efficiently concentrate the target antigen in preparation for the subsequent steps (e.g., buffer replacement, sterile filtration, formulation).

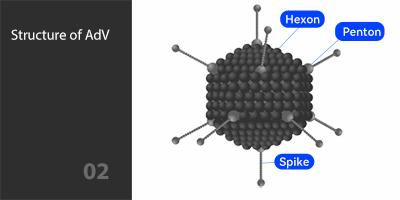

Concentration of viral vectors: For viral vector vaccines (e.g., adenovirus, lentivirus, AAV vector vaccines), TFF is a critical step for concentrating the viral particles and increasing the titer.

Downstream Clarification Concentration: After cell culture or fermentation, the target concentration in the initial clarification (e.g., deep filtration, centrifugation) is usually low and needs to be concentrated by TFF in order to reduce the sample volume and processing time of the subsequent chromatography columns.

Chromatographic eluent concentration: The eluent after chromatographic purification (e.g., ion exchange, molecular sieve, affinity chromatography) is usually large in volume and low in concentration, so TFF can efficiently concentrate the target antigen in preparation for the subsequent steps (e.g., buffer replacement, sterile filtration, formulation).

Concentration of viral vectors: For viral vector vaccines (e.g., adenovirus, lentivirus, AAV vector vaccines), TFF is a critical step for concentrating the viral particles and increasing the titer.

2、Buffer exchange/filtration:

Purpose: To exchange the target antigen from one buffer environment to another that is more suitable for subsequent processes (e.g., formulation, storage, lyophilization) or for the removal of small molecule impurities (salts, sugars, alcohols, inhibitors, endotoxin precursors, free nucleic acids, etc.).

Applications:

Interchromatography Buffer exchange: Between different chromatography steps, the target needs to be displaced into the equilibrium buffer required for the next chromatography step.

Removal of small molecule impurities: Wash filtration mode effectively removes small molecule additives (e.g., culture fluid components, protease inhibitors), salts, alcohols (e.g., solvents used for inactivation or precipitation), endotoxins, and small molecule metabolites.

Pre-formulation adjustment: Displacement of the target antigen into the final formulation buffer (containing stabilizers, adjuvant-compatible buffers, etc.) prior to final formulation of the vaccine preparation.

Post-inactivation treatment: After chemical inactivation (e.g. with formaldehyde, β-propiolactone), the inactivator and its by-products need to be completely removed, and TFF filtration is an efficient method.

3、Initial Clarification/Removal of Impurities:

Purpose: As a supplement or alternative to deep filtration or centrifugation, to remove cellular debris, large aggregates, some host cell proteins and nucleic acids.

Applications:

Cell Culture Harvest Fluid Clarification: Tangential flow microfiltration using microfiltration membranes with larger pore sizes (e.g., 0.1-0.65 µm) effectively removes cells and large debris, resulting in a more clarified feed solution for downstream purification. It is less likely to clog than dead-end filtration.

Removal of Macromolecular Aggregates: Remove protein aggregates or viral aggregates that may form in the later stages of purification.

4、Virus Removal/Sterility Assurance:

Purpose: Using ultrafiltration membranes with specific pore sizes (typically ≤20 nm or smaller), bacteria, mycoplasma and even small virus particles can be removed (as a de-viralization filtration step).

Applications:

Final Sterilization Filtration Pre-treatment: Used as a pre-step to final 0.2 µm or 0.1 µm sterile filtration to reduce the burden on sterile filtration membranes and prolong their life.

Specific Virus Removal: May be used to remove specific small viruses (subject to rigorous validation) in plasma-derived or certain cell culture-derived vaccine processes.

5、Continuous Production Process:

Purpose: TFF is easier to integrate into modern continuous bioprocesses due to its continuous or semi-continuous operating characteristics.

Applications: Downstream of continuous perfusion cell culture, TFF can be used directly for continuous harvesting and initial concentration of the products in the cell culture broth.

Applications: Downstream of continuous perfusion cell culture, TFF can be used directly for continuous harvesting and initial concentration of the products in the cell culture broth.

-

Benefits of Tangential Flow Filtration

1、Protection of antigenic activity: Tangential flow filtration is a gentle operation process, compared with traditional centrifugation and precipitation methods, it has less shear force on vaccine antigen, and can better protect the structure and activity of antigen, which is crucial for maintaining the immunogenicity of vaccine.

2、High efficiency and high throughput: Tangential flow filtration can process a large amount of feed solution in a short time, realizing efficient concentration and purification. Its high throughput can meet the needs of large-scale vaccine production, improve production efficiency and reduce production costs.

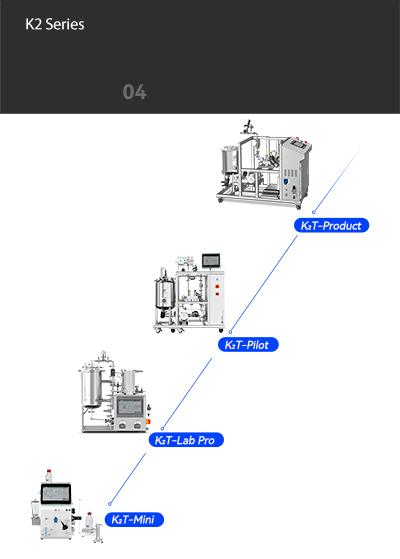

3、Flexibility and scalability: Tangential flow filtration system can be flexibly configured and adjusted according to different vaccine production processes and needs. It can easily cope with both small-scale laboratory research and large-scale industrial production, and can realize seamless amplification from laboratory to large-scale production, providing great convenience for vaccine R&D and production.

2、High efficiency and high throughput: Tangential flow filtration can process a large amount of feed solution in a short time, realizing efficient concentration and purification. Its high throughput can meet the needs of large-scale vaccine production, improve production efficiency and reduce production costs.

3、Flexibility and scalability: Tangential flow filtration system can be flexibly configured and adjusted according to different vaccine production processes and needs. It can easily cope with both small-scale laboratory research and large-scale industrial production, and can realize seamless amplification from laboratory to large-scale production, providing great convenience for vaccine R&D and production.

-

Hollow Fiber & Cassette

1、Hollow fiber shear force is low, especially suitable for sensitive biological products (such as live viruses, VLP, easy to aggregate proteins, exosomes), the vaccine active ingredients (such as antigenic conformation, viral integrity) better protection.

2、Cassette consist of multiple layers of flat membrane sheets (material e.g. PES, RC) laminated with a guide mesh to form parallel flow paths. If the sample is not sensitive to shear, the screen of the membrane packs improves the mass transfer efficiency, which in turn improves the filtration throughput and speed, including the concentration of the sample.

The application of tangential flow filtration technology in vaccines has injected a powerful impetus into the development and production of vaccines. In the era of vaccine R&D evolving towards modularization and continuous manufacturing, those fluid trajectories jumping on the membrane surface are weaving a precise manufacturing network covering from gene drugs to virus particles. What flows in this network is not only the drug solution, but also the innovative gene that breaks through the traditional production boundary. With its unique separation and purification advantages, it shines in the concentration of virus particles, the preparation of polysaccharide conjugate vaccines, buffer replacement, etc., which helps vaccine companies to improve product quality, reduce production costs and enhance market competitiveness.

2、Cassette consist of multiple layers of flat membrane sheets (material e.g. PES, RC) laminated with a guide mesh to form parallel flow paths. If the sample is not sensitive to shear, the screen of the membrane packs improves the mass transfer efficiency, which in turn improves the filtration throughput and speed, including the concentration of the sample.

The application of tangential flow filtration technology in vaccines has injected a powerful impetus into the development and production of vaccines. In the era of vaccine R&D evolving towards modularization and continuous manufacturing, those fluid trajectories jumping on the membrane surface are weaving a precise manufacturing network covering from gene drugs to virus particles. What flows in this network is not only the drug solution, but also the innovative gene that breaks through the traditional production boundary. With its unique separation and purification advantages, it shines in the concentration of virus particles, the preparation of polysaccharide conjugate vaccines, buffer replacement, etc., which helps vaccine companies to improve product quality, reduce production costs and enhance market competitiveness.