New Design: Minimalist Integrated Design, Evolved Efficiency and Safety

HOLVES has redesigned its products based on integrated and modular concepts. By eliminating redundant structures, it enhances performance while ensuring operational safety. The new appearance not only establishes a professional visual identity but also drives deep optimization of internal structures and overall layout.

- Hardware Design Innovation: Features a streamlined structure and modular layout to enhance space utilization and operational convenience.

- Software Interface Upgrade: Equipped with the all-new 3.0 intelligent control system, leveraging “Process Autopilot” and dual-screen collaboration to simplify complex process settings and provide clearer status monitoring at a glance.

- Integrated Interactive Experience: Based on full-terminal IoT adaptability, hardware and software work in deep synergy to seamlessly connect device status visualization with remote control.

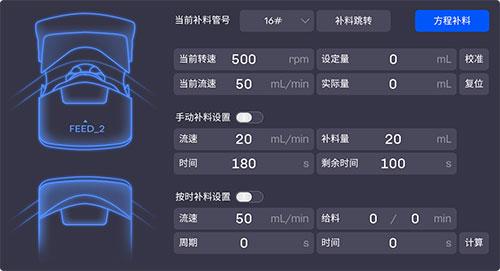

Feed-Sup® Intelligent Feeding System: Intelligent Feeding, Precisely Aligned with Growth Curves

HOLVES Feed-Sup® Feeding System is specifically designed to enhance the efficiency and yield of cell culture and fermentation processes by achieving precision and automation in the feeding process. Through multiple intelligent control modes, it enables precise regulation by coordinating parameters such as pH and dissolved oxygen (DO), ensuring nutrient supply precisely matches the actual metabolic demands of the microbial cells. This maximizes target product yield and batch-to-batch consistency.

- Supports Manual/Automatic Modes: Flexibly switch between modes to accommodate both process development stages and fully automated operation for large-scale production.

- Intelligent Cascade Control: Positive and negative feedback cascade control capabilities with pH, DO, and other sensors to achieve dynamic equilibrium of metabolic environmental parameters.

- Multi-Model Feed Strategy: Built-in algorithms including exponential feed and equation feed models perfectly align with microbial growth, enabling precise control for high-density fermentation.

H-Mix® Mixing System: Uniform Mixing, Gentle Power

Agitation is the core function of a bioreactor. HOLVES is designed with the industry's first H-NM® 3D Innovative no machine seal, eliminating the contamination risks and maintenance burdens associated with traditional mechanical seals. Optimized through computational fluid dynamics (CFD), it creates a uniform and gentle mixing environment throughout the entire culture volume.

- Patented Sealing Technology: Utilizing the exclusive patented H-NM® 3D technology, it eliminates the leakage risks, bacterial infections, and microbial breeding dead angle associated with mechanical seals. Operation is also quieter and smoother.

- Superior mass transfer rate: Optimized flow field distribution ensures rapid dissolution and uniform distribution of gases such as oxygen, meeting high oxygen demand requirements.

- Simple to use: No installation guidance or maintenance required, significantly reducing operational costs and downtime.

- Wide applicability: Customizable mixing systems tailored to cell types and culture scale, flexibly adapting to process requirements.

Metal-Tri® Audit Trail: Data Integrity, Process Traceability

Under stringent regulations, data integrity serves as the cornerstone of product quality assurance. The HOLVES audit trail system based on cryptographic modules and an operation log database enables seamless recording of equipment operations throughout their lifecycle and implements tiered permission management, ensuring the integrity and trustworthiness of production data.

- Process Tracking Log: Automatically records user logins, parameter modifications, operational commands, alarm events, and other actions with timestamps accurate to the second.

- Data Security Protection: Data is stored with real-time encryption and supports three-tier permission controls (view/export/delete) to prevent unauthorized data leaks and tampering.

- Biometric Module: The HMI interface features a built-in independent audit view. The next-generation system will integrate biometric technology to further enhance operational security.

Smart-SC® Intelligent Sequential Control: One-Click Drive, Smart Production

HOLVES Intelligent Sequential Control System achieves one-click automation throughout the entire process from inoculation to harvest via multi-stage control of customizable parameters including temperature, pH, stirring, and feed addition. This significantly reduces manual intervention, ensures high batch-to-batch consistency, and supports seamless scale-up from process development to large-scale production.

- Multi-stage process configuration: Supports multi-stage, precise matching of parameters such as temperature, pH, dissolved oxygen (DO),stirring and feeding to meet the requirements of each fermentation stage.

- Highly automated operation: Automated operation of the whole process, reducing manual intervention by more than 70%, lowering operational errors, and saving a lot of labor and time costs.

- Process adaptability: The control logic can be flexibly adjusted according to the process selection to meet the whole cycle of adaptation from R&D to production.

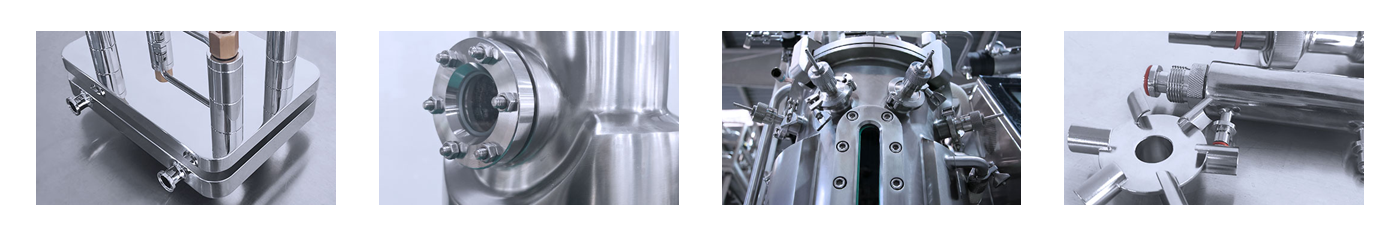

Precision processing: Make quality products with heart

Superior equipment performance begins with precision craftsmanship in every component. HOLVES insists on utilizing advanced machining centers and manufacturing processes to perform high-standard precision machining and treatment on every surface that comes into contact with the product, ensuring exceptional corrosion resistance, easy cleanability, and extended service life.

- High-precision surface polishing: The inner surface employs a stainless steel mirror polishing process, achieving a Ra≤0.4 on material-contact surfaces. This effectively prevents microbial retention and can be easily cleaned and sterilized.

- Professional Welding Technology: HOLVES' welding technology ensures all pipe welds are smooth, uniform, and defect-free, meeting ASME BPE standards.

- High Quality Material Selection: Core components utilize high-quality materials such as AISI 316L stainless steel to ensure compatibility with process fluids and equipment durability.