Intelligent Bioprocess Platform

A bioreactor precisely controls key process parameters—such as temperature, pH, dissolved oxygen (DO), and agitation speed—to provide optimal growth and metabolic conditions for microorganisms, animal and plant cells, or enzymes. This enables efficient production of target products including recombinant proteins, monoclonal antibodies, vaccines, GLP‑1 peptides, and ADC therapeutics.

From laboratory scale glass bioreactors to pilot scale and full commercial stainless steel systems, configurations and volumes can be flexibly matched to different stages of R&D and manufacturing. With advanced automation and digital monitoring, bioreactors ensure high activity, high purity, and consistent product quality, making them an indispensable component of modern biopharmaceutical production.

GMP Four Valve Manifold System

The GMP four valve manifold is designed for critical operations such as media addition, inoculation, sampling, and transfer. It meets stringent aseptic requirements while maintaining operational flexibility. Mainstream designs include independent diaphragm valve assemblies and forged integrated multi channel valve blocks.

- Full process coverage: Feeding, inoculation, base addition, perfusion harvest, sampling, and final collection are all connected via the four valve manifold.

- Dual sterilization modes: Supports both in situ sterilization synchronized with the vessel and independent sterilization, eliminating dead legs and ensuring GMP compliance.

- Precise monitoring: Cold point temperature monitoring provides real time sterilization status and process assurance.

- Stable and reliable: Uses internationally recognized brands such as GEMÜ, Bürkert, and Hebron, with interchangeable valves to suit different process and maintenance requirements.

Agitator Selection

In stirred bioreactors, impeller selection is a critical factor. Proper impeller design ensures uniform distribution of cells, gases, and nutrients, prevents cell sedimentation, maintains temperature homogeneity, and directly impacts cell viability, oxygen transfer efficiency, and final yield.

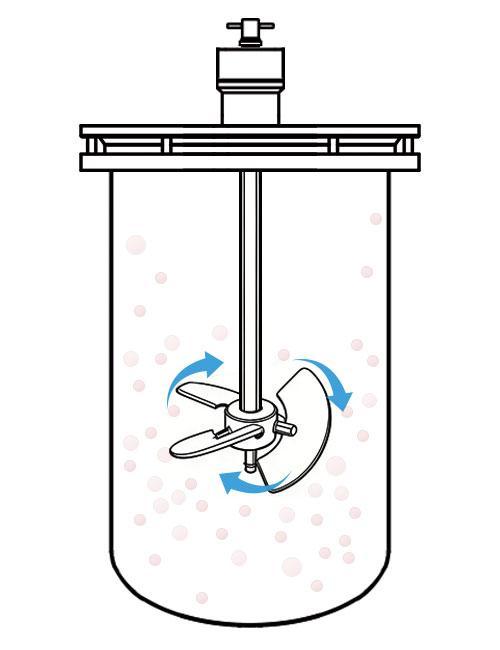

Pitched‑Blade Impeller

Generates axial and radial flow for enhanced mixing, delivering higher oxygen transfer rates than unidirectional helical impellers. Suitable for animal cell culture and suspension or microcarrier cultivation of shear-sensitive cell lines.

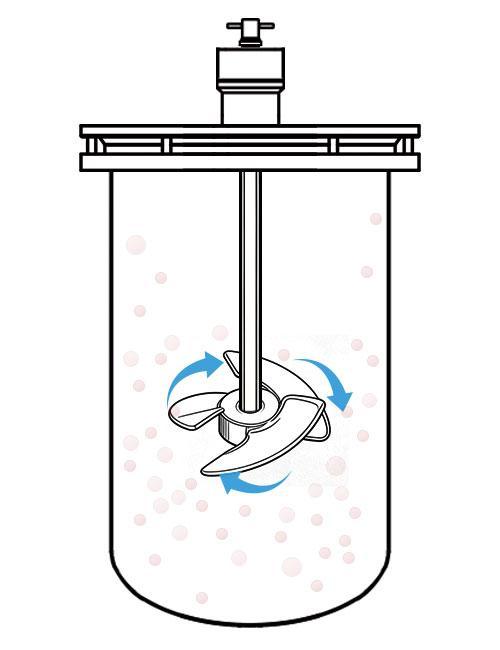

Helical Impeller

Flat or concave blade front with a concave back, designed to generate axial flow with gentle mixing and minimal cell damage. Used for liquid–liquid mixing, temperature homogenization, prevention of solids settling, and selected anaerobic cultures.

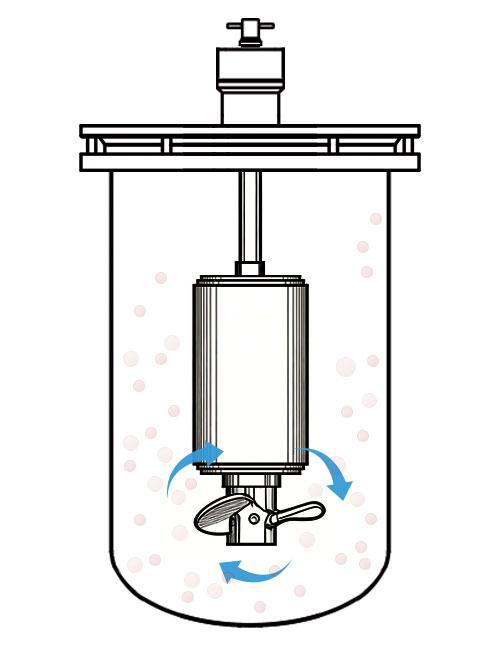

Cell‑Lift Impeller

Provides gentle mixing and enables cell-free medium harvest for downstream purification, also suitable for protein-secreting processes. Applied in microcarrier-based adherent cell culture and extremely shear-sensitive cell lines applications.

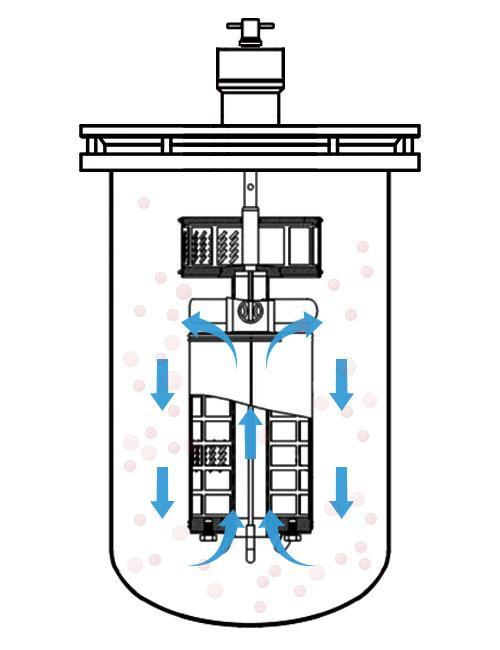

Rotating Filter Impeller

Uses fine mesh apertures on the outer screen to retain cells on microcarriers while allowing medium exchange. Designed for shear-sensitive animal cell lines in batch, fed-batch, and continuous perfusion cultures with stable cell retention performance.

Selection Principles

- Minimize cell damage: For shear sensitive or aggregation prone cells (e.g., filamentous fungi), select gentle mixing impellers such as helical or cell lift designs.

- Match oxygen demand: Aerobic cultures benefit from high KLa impellers such as pitched blade or Rushton turbines.

- Adapt to the culture system: Choose impellers with integrated separation or filtration functions when immediate product separation is required.

Aeration Strategies

The aeration system is critical for maintaining metabolic activity and environmental stability. By precisely controlling gas composition, flow rates, and delivery methods, it supports oxygen supply and pH regulation across different culture phases. Four core aeration configurations are available:

-

Airflow

Mass flow controllers (MFCs) precisely regulate gas flow. Check valves prevent backflow, flowmeters provide real time indication, and pressure gauges monitor vessel pressure for stable operation. -

O₂ Enrichment

A bypass oxygen enrichment design with independent MFCs and check valves for air and oxygen. Automatic oxygen supplementation with visualized total flow and real time vessel pressure monitoring. -

Gas Flow Ratio Control

Independent mixing of Air, O₂, CO₂, and N₂. CO₂ flow is automatically adjusted based on pH, while DO feedback dynamically controls gas ratios. Total flow is centrally displayed for complex process conditions. -

Advanced Additive Flow

Five channel MFC control: four gases mixed for deep sparging, plus one independently controlled shallow aeration line. Dual aeration modes ensure uniform and efficient gas transfer.

Aseptic Sampling Device

Traditional sampling from stainless‑steel bioreactors is often labor‑intensive, time‑consuming, and prone to contamination and biosafety risks. HOLVES has developed a dedicated aseptic sampling device to provide reliable sampling protection for sterile processes.

The aseptic sampling device safeguards your production process and effectively prevents cross-contamination. Its fully closed design ensures complete separation between the sample and the sampling point, significantly reducing product loss and operational risk.

- Fully closed design prevents cross-contamination and protects process integrity. Advanced sealing technology and aseptic workflows completely isolate samples from the external environment.

- Simplified operation enables fast sampling, significantly improving efficiency and reducing human error.

- Seamless integration with stainless-steel equipment without additional modification.

- Separation of sample and sampling point minimizes loss of high-value products.

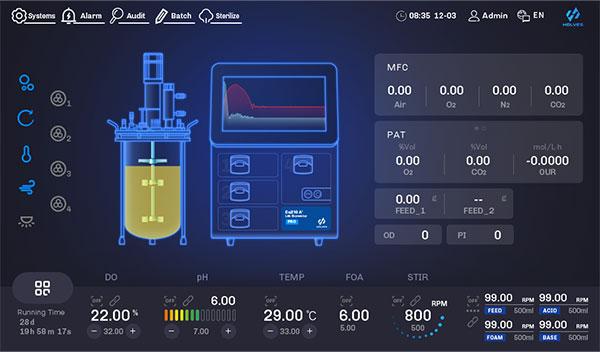

HF-Control 3.0 Holographic Intelligent Control System

In 2025, HOLVES once again cooperates with the original design team to launch the third-generation graphical interface - HOLVES 3.0 Holographic Intelligent Control System, which integrates the sense of design and practicability, realizing a leapfrog upgrade. On the basis of inheriting the core advantages of the previous generation, the system integrates the car-level interaction design and the concept of "Process Autopilot", through the dual-screen coordination structure of the main and secondary screens, with the ability of the whole terminal Internet of Things (IoT) adapted to convert the complex fermentation control into a more intuitive, smarter, and more interconnected control experience.

- Automotive-grade UI design: The interface adopts a dark theme, with a centralized minimalist design and layered architecture, presenting the complex process data in a more intuitive and multi-dimensional way.

- Dual-screen synergy: Main screen integrated operation control interface, support multi-level menu view. The bottom of the fixed sub-screen display, the core data visualization area, real-time dynamic display of key parameters trends.

- Safe and compliant data management: It supports data export, has built-in multi-level permission management, requires authorization for critical operations, meets GMP data traceability requirements.

- Flexible Multi-Parallel Fermenter Synergy Control: For complex systems such as multi-parallel fermenters and cascade fermenters, it supports one-key switching between single vessel and multi-vessel modes, with a unified operation interface, realizing efficient synergy in parallel management of multiple processes.

Discover Our Products

Microcarriers

Designed for adherent cell lines, significantly improving culture efficiency and productivity.

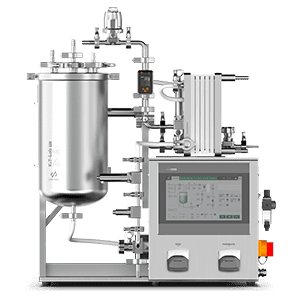

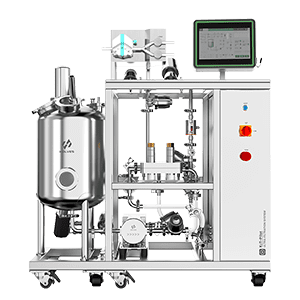

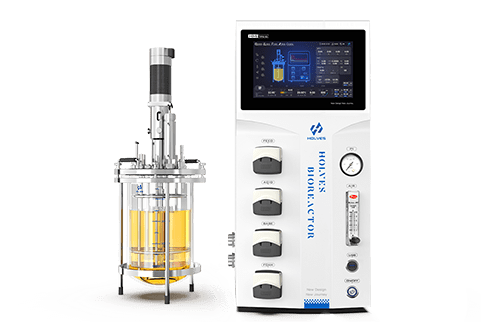

Eu210 Bioreactor

A flagship fermentation system offering exceptional operational stability and extensive scalability.

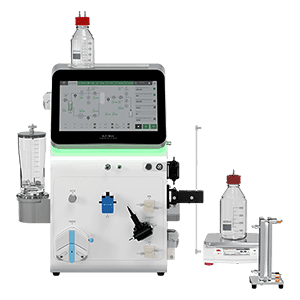

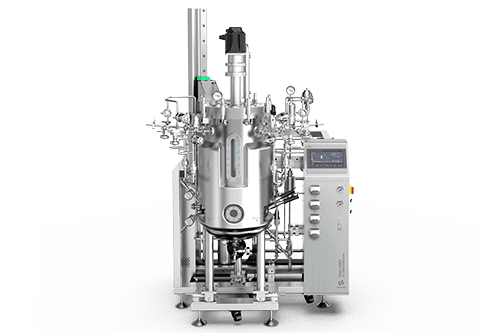

Omini Cell510 Bioreactor

Process development, pilot-scale, and GMP clinical production. Customizable.