Discover our products

Cla210 Series Fermenter

Laboratory Glass Fermenter | Classic Fermentor

Eu210 Series Fermenter & Bioreactor

Laboratory Advanced Fermenter and (Benchtop) Bioreactor

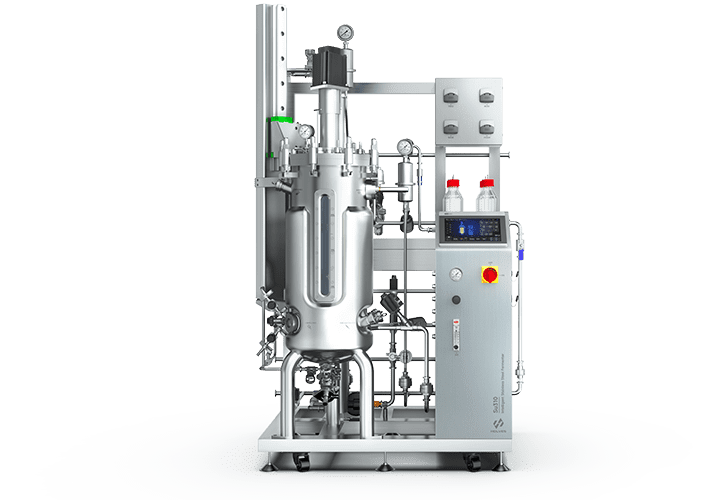

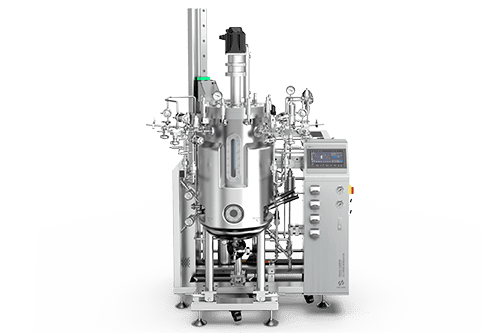

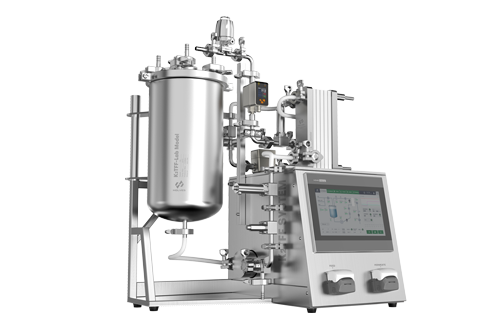

Su310 Series Stainless Steel Fermenter

Intelligent Stainless Steel Fermenter

HPB Mini Series Parallel Bioreactor

Laboratory Parallel Bioreactor | Multi-parallel Bioreactor

Omini Cell510 Bioreactor

Process Development, Scale-Up, and GMP Clinical Sample Production

Microcarriers

Microcarriers for Cell Culture

Twin220 Series Parallel Fermenter

Laboratory Duplex Fermenter | Parallel Fermenter

Hub240 Series Parallel Fermenter

Laboratory Integrated Parallel Fermenter

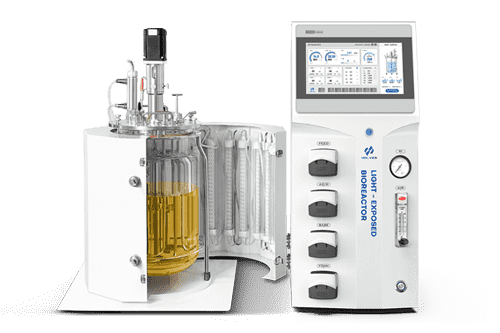

Pb210 Series Light-exposed Bioreactor

Photobioreactor | Light-exposed Bioreactor

Tangential Flow Filtration (TFF) Systems

Ultrafiltration and Diafiltration (UF/DF) | K₂T Series TFF Systems

Application and Scale-Up Process of Ceramic Membrane Filtration System

K₂C Series Ceramic Membrane System | Scale-Up and Application

K₂P Series Bio Intelligent Pump

Four-piston Diaphragm Pump as The Power System

Vessel Manufacturing process

As the most direct mechanical part in the process of bacterial/cell culture, the vessel is the most important manufacturing part of the fermenter. The vessel body of the fermenter must conform to the sanitary design, requiring no residue, no welding, no burr, and high requirements for materials and production and processing. At the same time, reasonable design can make the vessel manufacturing become more easy to process and meet the requirements. HOLVES’ engineers have been committed to design outstanding vessel structure, also has been creating outstanding vessel processing team. At present we have excellent quality design and processing team in China, can provide users with excellent vessel.

HOLVES' current vessel processing is mainly from our partners, who have over ten years of vessel processing experience, providing mature and reliable vessel manufacturing for our fermenters.

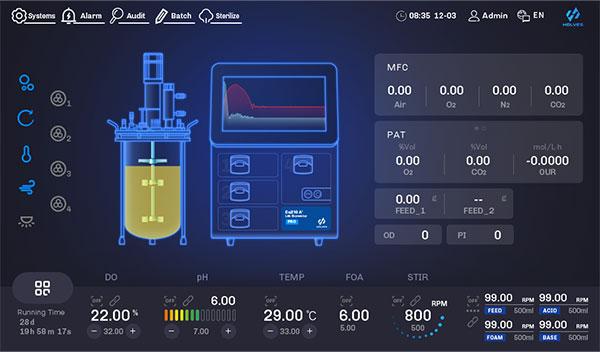

HF-Control 3.0 Holographic Intelligent Control System

In 2025, HOLVES once again cooperates with the original design team to launch the third-generation graphical interface - HOLVES 3.0 Holographic Intelligent Control System, which integrates the sense of design and practicability, realizing a leapfrog upgrade. On the basis of inheriting the core advantages of the previous generation, the system integrates the car-level interaction design and the concept of "Process Autopilot", through the dual-screen coordination structure of the main and secondary screens, with the ability of the whole terminal Internet of Things (IoT) adapted to convert the complex fermentation control into a more intuitive, smarter, and more interconnected control experience.

- Automotive-grade UI design: The interface adopts a dark theme, with a centralized minimalist design and layered architecture, presenting the complex process data in a more intuitive and multi-dimensional way.

- Dual-screen synergy: Main screen integrated operation control interface, support multi-level menu view. The bottom of the fixed sub-screen display, the core data visualization area, real-time dynamic display of key parameters trends.

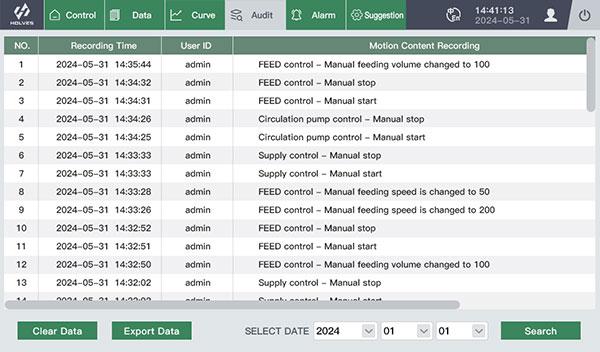

- Safe and compliant data management: It supports data export, has built-in multi-level permission management, requires authorization for critical operations, meets GMP data traceability requirements.

- Flexible Multi-Parallel Fermenter Synergy Control: For complex systems such as multi-parallel fermenters and cascade fermenters, it supports one-key switching between single vessel and multi-vessel modes, with a unified operation interface, realizing efficient synergy in parallel management of multiple processes.

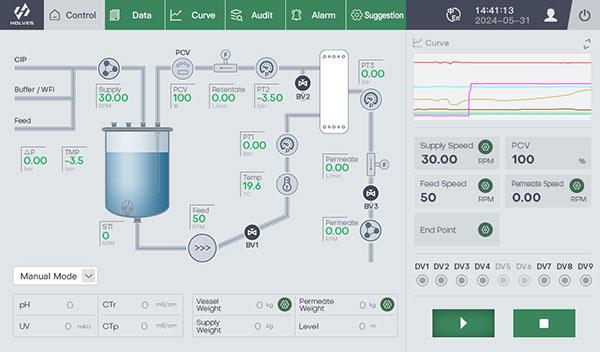

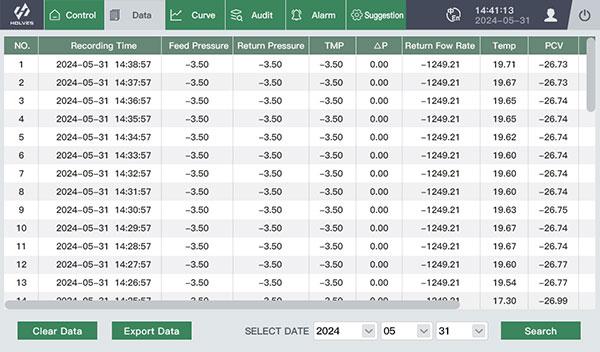

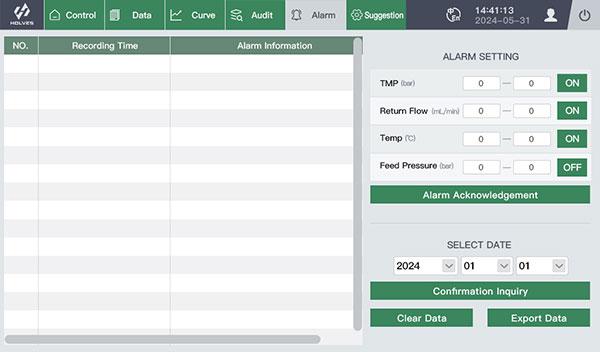

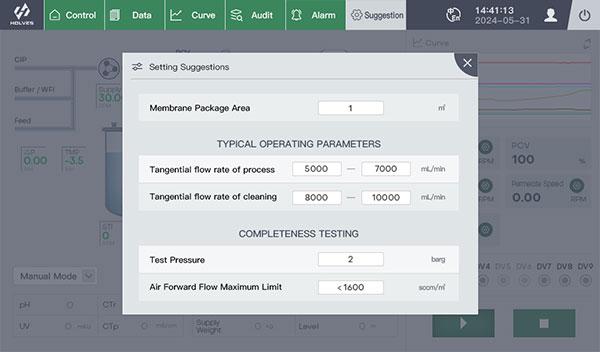

K₂T-Control Ultrafiltration Control System

The HMI interface design of the HOLVES TFF system provides an excellent operating experience with its efficient, intuitive and intelligent features. This design not only improves ease of operation and system reliability, but also ensures compatibility with future trends in automated production by integrating the latest Industry 4.0 IoT technology.

- Intuitive User Interface: Making it possible for the user to quickly identify problems and adjust the operation in time to optimize the production process.

- Convenient Operation Process: To realize automatic concentration and dialysis, and preset concentration, filter washing and other process procedures.

- Intelligent Monitor and Control: Online monitoring and control of various parameters.

- Automation and IoT Technology: HOLVES has adopted the new generation of Industry 4.0 IoT technology.

- Remote Access and After-sales Support: The HMI interface allows remote access, users can monitor and control the process remotely.

Upstream and Downstream Process

Upstream and downstream processes are two core stages in biotech manufacturing.

The upstream process focuses on culturing cells in bioreactors or fermenters to efficiently produce target biomolecules. It centers on optimizing culture conditions for a range of organisms, from basic microbes to genetically engineered cell lines.

The downstream process is responsible for isolating and purifying the target product from the upstream mixture. It employs various steps (e.g., cell disruption, filtration, chromatography) to remove impurities. Key equipment such as TFF systems and Ceramic Membrane Filtration systems are often utilized to ensure the final product meets the required purity and concentration.