Fermenter is not a static container, it is not only the core container of industrial biological reaction, but also the key fortress of production safety and product quality of the enterprise. Every valve rotation, aseptic aeration, are testing the stability of the operation of this set of precision systems. Neglect of routine maintenance brought about by the slightest wear and tear or accumulation of impurities, will eventually evolve into the cost of frequent shutdowns, the frequent occurrence of bacterial crisis, product batch scrapped. One failure repair is the sunk capital of enterprise production. A set of rigorous maintenance procedures, is to ensure its long-term efficient and safe operation of the core hub.

This guide is designed to dismantle the inner logic of maintenance techniques to keep fermentors in optimal condition at all times in order to ensure core equipment value.

This guide is designed to dismantle the inner logic of maintenance techniques to keep fermentors in optimal condition at all times in order to ensure core equipment value.

-

Routine cleaning and sterilization

At the end of each fermentation cycle, thorough cleaning and sterilization is the primary line of defense to block the chain of microbial contamination. Residual nutrients are a breeding ground for stray bacteria, and stubborn biofilms may harbor pathogens. The high-frequency CIP program (Cleaning in Place) is initiated immediately at the end of fermentation, with a fixed use of specific temperatures, concentrations of detergents and cleaning flow rates. Cyclic SIP (Sterilization In Place) is a steam environment maintained at 121°C and 0.11 MPa to completely remove all active microorganisms from the vessel.

1. Stainless steel fermenter: Focus on CIP/SIP ball/nozzle coverage to ensure no dead spots. Resistant to broader spectrum or slightly more concentrated cleaners/sanitizers.

2. Laboratory fermenter: Cleaners and sanitizers need to be chosen with extreme care to avoid corrosion of the glass or silicone seals by strong bases, hydrofluoric acid, etc. Manual cleaning ratio is higher, need to operate gently to prevent scratching the glass wall. Pay attention to the rate of temperature rise and fall when sterilizing to avoid glass breakage caused by thermal shock. Neglecting any part of the process may set the stage for the next infection.

3. Dead Space Removal: Attention should be paid to hydrodynamically weak areas such as sampling valves, inoculation ports, exhaust filter connections, and the perimeter of the mixing shaft seal, which should be cleaned by manual disassembly if necessary.

3. Dead Space Removal: Attention should be paid to hydrodynamically weak areas such as sampling valves, inoculation ports, exhaust filter connections, and the perimeter of the mixing shaft seal, which should be cleaned by manual disassembly if necessary.

-

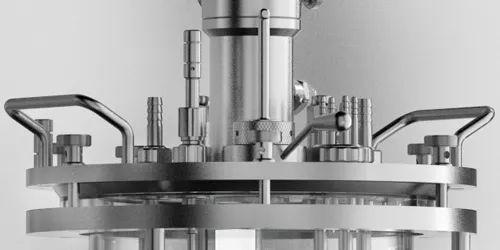

Sealing check

Fermenters need to operate stably under positive and negative pressure, and the slightest leakage may lead to leakage of culture liquid, gas leakage or bacteria contamination. We need to focus on key connection parts such as fermentor flanges, sampling valves, inoculation ports, electrode ports, etc., and regularly check the integrity, elasticity and signs of aging of seals such as O-rings and gaskets. Pressure holding test when the vessel is pressurized (empty or solid) is an effective means to verify the overall sealing.

1. Stainless steel fermenter: Flange surface flatness, bolt tightening torque is the focus of the inspection, a wide range of seal materials (such as EPDM, FKM, Silicone).

2. Laboratory fermenter: Because laboratory fermenters are made of glass, top connections and electrode ports have always been high leakage areas. The seals are easy to be aged and deformed, so they need to be checked and replaced more frequently. Pressurization testing needs to be done under the guidance of professionals, equipped with protective facilities (explosion-proof cover, safety gloves, goggles, etc.) and strictly control the test pressure within the safe range of the glass vessel, and overpressure is absolutely prohibited.

1. Stainless steel fermenter: Flange surface flatness, bolt tightening torque is the focus of the inspection, a wide range of seal materials (such as EPDM, FKM, Silicone).

2. Laboratory fermenter: Because laboratory fermenters are made of glass, top connections and electrode ports have always been high leakage areas. The seals are easy to be aged and deformed, so they need to be checked and replaced more frequently. Pressurization testing needs to be done under the guidance of professionals, equipped with protective facilities (explosion-proof cover, safety gloves, goggles, etc.) and strictly control the test pressure within the safe range of the glass vessel, and overpressure is absolutely prohibited.

-

Sensor Calibration

Sensors for temperature, pH, dissolved oxygen (DO), pressure, etc. are the “eyes” of the fermentation process. Data deviation will lead to uncontrolled process parameters, which may affect the yield and quality, or cause batch failure. The calibration program is based on the manufacturer's recommendations and process requirements. Temperature probes need to be calibrated regularly with multiple points in a standard solution; pH electrodes are usually the most frequently calibrated, and it is best to calibrate them with a standard buffer each time; dissolved oxygen electrodes need to be calibrated at zero and full point.

1. General principle: The calibration frequency depends on the intensity of use, process criticality and sensor stability.

2. Points of difference: Laboratory glass fermentors often require frequent disassembly of electrodes for offline calibration or replacement, and aseptic operation and interface sealing checks during disassembly are particularly important. Stainless steel fermentors are preferred for in-situ calibration or use a quick connect design to minimize the risk of contamination.

1. General principle: The calibration frequency depends on the intensity of use, process criticality and sensor stability.

2. Points of difference: Laboratory glass fermentors often require frequent disassembly of electrodes for offline calibration or replacement, and aseptic operation and interface sealing checks during disassembly are particularly important. Stainless steel fermentors are preferred for in-situ calibration or use a quick connect design to minimize the risk of contamination.

-

Preventive Maintenance & Monitoring

In addition to some of the above fixed maintenance schedules, regular checking of the condition of mechanical components makes proactive intervention stronger than reactive repairs.

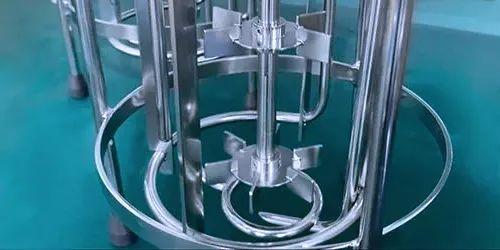

1. Stirring system: Monitor bearings and shafts for early detection of mechanical hazards such as misalignment of stirring shafts and bearing wear. Check the paddles for deformation, corrosion or bio-attachment, etc.

1. Stirring system: Monitor bearings and shafts for early detection of mechanical hazards such as misalignment of stirring shafts and bearing wear. Check the paddles for deformation, corrosion or bio-attachment, etc.

2. Valve and piping: Confirm the precision and response time of valve opening and closing, and check the stability of piping support.

3. Regular replacement: Regular replacement of air pre-filters, respirator cartridges and other consumables is the key to safeguarding the sterility barrier.

3. Regular replacement: Regular replacement of air pre-filters, respirator cartridges and other consumables is the key to safeguarding the sterility barrier.

A biopharmaceutical company's production line has seen a 60% reduction in downtime and a more than 75% reduction in batch failures due to bacterial contamination after the implementation of comprehensive enhanced maintenance. Similarly, a university laboratory standardized the maintenance process of its multiple glass fermenters, reducing the failure rate of critical experiments due to equipment problems by 40%, greatly improving research efficiency and data reliability.

The stable operation of fermenters is based on consistent and professional maintenance, which is tailored to the type of equipment (glass/stainless steel). HOLVES understands the core needs of bioprocesses. We not only offer high-performance glass and stainless steel fermentors from laboratory to production, but also customized maintenance strategies and technical training. Contact the HOLVES team for a maintenance assessment to keep your fermentation process running efficiently and reliably, no matter how big or small it is.