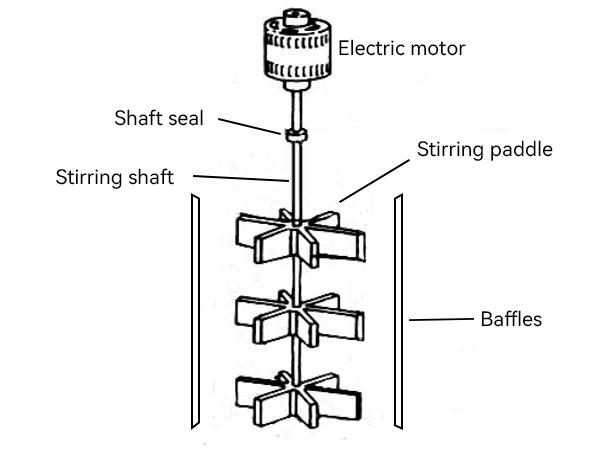

The motor and gearbox are to provide power for stirring; the stirring paddle and stirring shaft are the main parts of the operation; the shaft seal is to prevent the fermentation liquid from leaking out and contamination by stray bacteria; the baffle is to prevent large vortex on the liquid surface during stirring and promote the mixing of liquid in the tank.

THE EFFECT OF STIRRING

The basic structure of a stirred tank fermenter is a stirring shaft that extends into the tank at the top or bottom of the tank, and the shaft will be equipped with 2 to 4 stirring paddles.Stirring is to make the materials in the tank can be better mixed, which is conducive to the solid and nutrient contact adequately, facilitating the nutrient absorption and the dispersion of metabolites.In addition, stirring can also evenly disperse the air entering the tank, increasing the air-liquid contact area in the laboratory fermenter and facilitating the mixing of oxygen and fermentation broth.

CHOICE OF STIRRING PADDLES

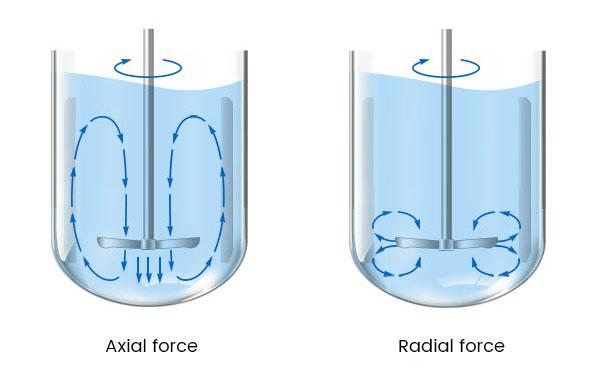

The main structure in the stirring system is the shaft and the paddle, so how to choose the paddle?Different types of stirrer blades produce different axial and radial forces, so it is necessary to choose the right stirrer for different cultures in fermentation process.

About the laboratory fermenter stirring principle, I believe you have a general understanding through this article.Stay tuned to HOLVES, after which we will explain how to solve the problem of foam generated in the tank during fermentation in laboratory fermenter.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.