The key to the large-scale industrialization and commercialization of animal cell culture technology lies in the design of a suitable bioreactor. Since animal cells are very different from microbial cells, traditional microbial reactors are obviously not suitable for large-scale culture of animal cells. First of all, it must meet the requirements of low shear and good mixing state, which can provide sufficient oxygen for cell growth and cell synthesis of products.

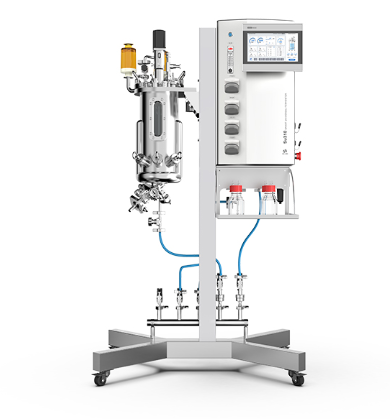

What types of bioreactors are commonly used in the laboratory? According to the reactor material, it can be divided into glass tank reactor, stainless steel reactor and disposable reactor.

(1) Glass tank bioreactor

At present, most of the reactors used for process development and research at home and abroad are mainly glass tanks, glass tank bioreactors with flexible configuration, powerful, simple operation, easy to upgrade and expand, etc., is the best choice to carry out animal cell culture and microbial fermentation research and development projects, can be used for animal cells, E. coli, yeast, fungi, insect cells and plant cell culture, etc.

(2) Stainless steel bioreactor

So far, the FDA-approved antibody drugs are basically produced in stainless steel reactors. Due to the low yield of antibodies in the early days, the production scale is mostly around 10,000L. Stainless steel reactors usually involve CIP modules, SIP modules, storage modules, etc., so the pipeline connection is very complex and requires high operator requirements.

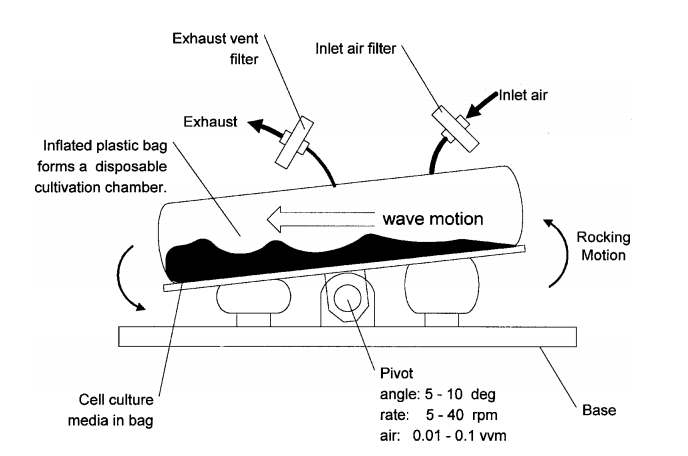

(3) Disposable bioreactor

Disposable bioreactor or disposable bioreactor after use is the use of disposable bags of bioreactors, compared with the traditional stainless steel reactor, the use of disposable reactors can all achieve a high degree of similarity, while also reducing production costs.

With the rapid development of cell line construction technology and medium development technology, cell density and antibody yield have increased dramatically, posing a serious challenge to large-scale cell culture.

In addition, since the main basis of reactor scale-up is still based on empirical scale-up principles, and there is still some controversy, such as the suitability of leaf tip rate as a scale-up principle. These factors undoubtedly increase the difficulty and risk of future antibody drug industrialization.

More questions to solve?

More Questions

More Questions

[VIRTUAL Address] HOLVES Su310 intelligent stainless steel fermenter is a new generation of pilot and small-scale production equipment, integrating hardware innovation and intelligent control. In the pharmaceutical industry, stainless steel fermenters are crucial for produ...

[Ceramic Membrane Filtration] Ceramic membrane filtration is a physical separation process that uses ceramic materials with porous structures to separate particles, microorganisms, and dissolved substances from liquids....

[Tangential Flow Filtration] The Application of Tangential Flow Filtration Cassettes...

[Four-Piston Diaphragm Pumps] What is a Four-Piston Diaphragm Pump? How Does a Four-Piston Diaphragm Pump Work? What Are the Key Advantages of Four-Piston Diaphragm Pumps?...

[Photobioreactor] Photobioreactors are specialized cultivation systems designed to grow photosynthetic microorganisms such as microalgae, cyanobacteria, and other photosynthetic cells under controlled environmental conditions. Lab-scale photobioreactor systems serve as...

[Fermenters] Optimizing Fermenters for Enhanced Production...

[Bioreactors] Biological Reactions in Bioreactors: Advanced Solutions for Efficient Fermentation...

[Tangential Flow Filtration] Tangential Flow Filtration (TFF) is a separation process widely used in various industries, especially in biopharmaceutical manufacturing, water treatment, and chemical processes....

[Small Spray Dryers] Learn the Basics of Small Spray Dryers...

[Fermenter] You can find the answer to the question about fermenter feed supplement……...