pH electrode daily maintenance for basic fermentation knowledge

# 1

Ready to install and use

- When opening the package, carefully check whether there is mechanical damage to the PH sensitive membrane glass, diaphragm (plain fired ceramic core) and vitreous body of the electrode.

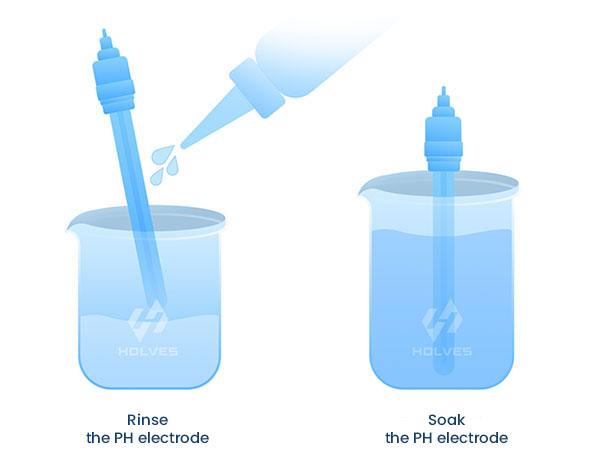

- Remove the drip set and clean the top of the electrode with pure water, and then gently wipe dry with wet paper towel or absorbent paper. Be careful not to rub the PH sensitive membrane to increase response time.

- Move the pH electrode to the vertical position to prevent bubbles in the memory of the PH-sensitive membrane glass bulb. If no wave body is filled or there are bubbles, gently shake the electrode to fill the bulb with liquid until there are no bubbles.

- The electrode can be soaked in acid buffer (pH4.01) for several minutes before use, rinse the glass bulb part with pure water, and then gently blot the glass bulb part with absorbent paper, and then in neutral buffer (pH6.86 or 7.00 etc.) for a few minutes to activate the electrode before starting the calibration.

# 2

pH electrode two-point calibration operation

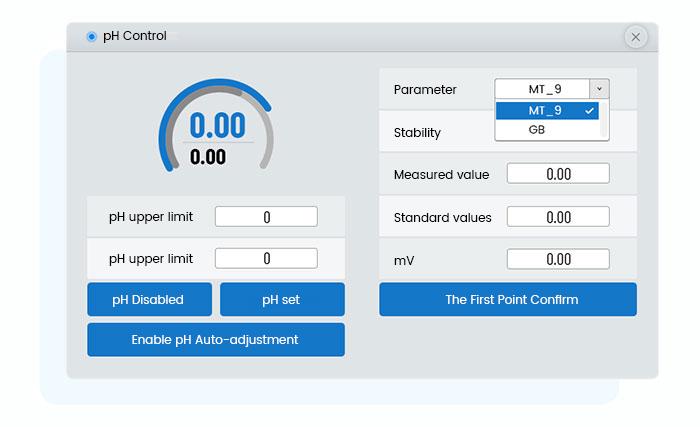

-

Before calibration, select parameters according to the buffer light type:

● [GB] refers to the use of the view in accordance with GB/T 27501-2011 standard buffer, generally used several buffer pH values of 4.00, 6.86 and 9.18. Its corresponding "stability", that is, the uncertainty of buffer is usually selected, ±0.02pH

● Holves generally uses METTLER TOLEDO InPro3030 series pH electrodes. The common number IMT9 corresponds to its brand of buffer solution, and the buffer wave pH value is 401, 7.00 and 9.21. The "stability" should be selected according to the type of buffer used. - Connect the electrode, rinse the electrode with pure water, and then gently blot the water on the probe with absorbent paper.

- Partially immerse the glass bulb in the first buffer (e.g.: pH =401) (the diaphragm should be completely immersed in the suitizer). After the standard value is stable (30 seconds to 60 seconds), click the first point to confirm, then the first point calibration is finished.

- Remove the electrode from the first buffer and rinse the electrode with pure water. After rinsing, gently blot the water on the probe with absorbent paper.

- Put the glass bulb is partially submerged in the second flush solution (e.g.: pH=9.18)(the diaphragm should be completely immersed in the buffer). After the standard value is stable (30 seconds to 60 seconds), click the second point to confirm. The second point calibration is finished, and wait for use (not too long).

# 3

Precautions for electrode calibration

- Please pay attention to the use of fresh buffer during calibration.

- place the electrode in buffer for 1min before the subsequent operation.

- After rinsing the electrode, only soft absorbent paper can be used to blot the water. Do not rub pH sensitive membrane.

- Electrode calibration cycle according to different use environment and accuracy requirements, please determine the appropriate calibration cycle on the premise of ensuring accuracy.

- Due to the Ph electrode probe is extremely fragile, so do not knock in the process in use.

# 4

pH electrode performance test

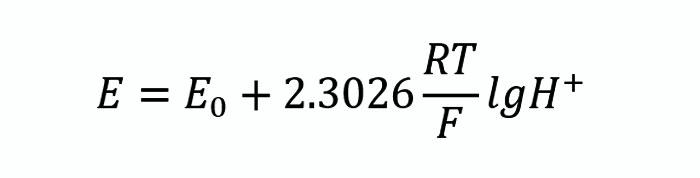

The pH electrode method is based on the principle of Nernst equation. The electromotive force of the electrode has a linear relationship with the pH value. Generally, two different pH buffer are used for calibration. To determine the slope of the curve. The commonly referred to as the pH electrode response slope, refers to the pH electrode used to convert the millivolt (mV) signal into pH value, it is measured by different buffer voltage difference, divided by the buffer difference value. This slope is an important indicator to determine whether the life of the plate is exhausted.

Specific operation method of slope test:

- Clean the electrode after two points calibration with pure water, and dry the well with soft absorbent paper.

- Adjust route parameters and stability according to the method used in the calibration above. The following takes MT standard as an example.

- First, the pH-7.00 buffer was used to measure the zero point, and the MV value was read out on the display screen. The pH electrode zero of HOLVES standard configuration is within 6.5~7.5 fan, and the installed electrode is normal.

- After cleaning the electrode, insert it into the standard buffer solution of pH=4.01 (denoted as pH1), read mV value (denoted as mV1) on the display screen.

- After cleaning the electrode, insert it into the standard buffer solution with pH=9.21 (denoted as pH2), and read mV value (denoted as mV2) on the display screen.

- Calculate the slope of the electrode, i.e. (mV1-mV2)/(pH1-pH2).

- According to Nernst equation, the ideal slope is 59mV/pH in the ideal state (25°C). That is, for every change in pH of the solution, the electrode generates a potential change of 59mv. The slope should be around 59mV/pH with ideal correction. If the slope is less than 53mV/pH or greater than 63mV/pH, replace the pH electrode with a new one. So when the correction the results are credible for positive slopes in the 53-63mV/pH range.

# 5

Cleaning of electrode

- Generally polluted water, 0.1mol/L NaOH or 0.1mol/L HCl, clean the electrode for several minutes.

- Grease or organic contamination clean the electrode with acetone or ethanol for a few seconds.

- Sulfide contamination (blackening of the diaphragm) is treated with sulfuric acid/HCl, and the glass bulb is partially immersed in the solution (the diaphragm should be submerged in the solution) until the diaphragm is colorless (at least 1 hour), and then soaked in 3mol/L At least 12 hours in KCI, fully flushed wells can be used after recalibration.

- Protein contamination (yellowing of diaphragm) Treat with gastrin/HCl, place glass bulb part in solution, make sure the membrane is submerged in solution (at least 1 hour), then rinse with distilled water, recalibrate.

# 6

Preservation of electrode

- After the end of each production cycle. Rinse the electrode head and diaphragm carefully with deionized water. Never dry out the measuring solution on these parts.

- Electrodes should not be stored in steam road water. When not used for a long time, it should be fully immersed in 3mol/L KCI or 9816 /viscolytTM electrolyte together with the electrode head and diaphragm.

- The electrode can not be dry for a long time, can not be stored on the surface with dry medium. If the electrode has been dried for several days due to an error, soak it in the normal storage electrolyte for several hours before use.

- Always check the connector for signs of moisture. If necessary, wash thoroughly with deionized water or alcohol, then dry it carefully.

More questions to solve?

More Questions

More Questions

[VIRTUAL Address] HOLVES Su310 intelligent stainless steel fermenter is a new generation of pilot and small-scale production equipment, integrating hardware innovation and intelligent control. In the pharmaceutical industry, stainless steel fermenters are crucial for produ...

[Ceramic Membrane Filtration] Ceramic membrane filtration is a physical separation process that uses ceramic materials with porous structures to separate particles, microorganisms, and dissolved substances from liquids....

[Tangential Flow Filtration] The Application of Tangential Flow Filtration Cassettes...

[Four-Piston Diaphragm Pumps] What is a Four-Piston Diaphragm Pump? How Does a Four-Piston Diaphragm Pump Work? What Are the Key Advantages of Four-Piston Diaphragm Pumps?...

[Photobioreactor] Photobioreactors are specialized cultivation systems designed to grow photosynthetic microorganisms such as microalgae, cyanobacteria, and other photosynthetic cells under controlled environmental conditions. Lab-scale photobioreactor systems serve as...

[Fermenters] Optimizing Fermenters for Enhanced Production...

[Bioreactors] Biological Reactions in Bioreactors: Advanced Solutions for Efficient Fermentation...

[Tangential Flow Filtration] Tangential Flow Filtration (TFF) is a separation process widely used in various industries, especially in biopharmaceutical manufacturing, water treatment, and chemical processes....

[Small Spray Dryers] Learn the Basics of Small Spray Dryers...

[Fermenter] You can find the answer to the question about fermenter feed supplement……...