In designing a bioreactor, the blade has a dual function. On the one hand, the rotating blade can drive the movement of the liquid in the reactor, thereby realizing the mixing of the substances in the liquid, which is conducive to the absorption of nutrients by the cells in the entire reactor. On the other hand, the rotation of the blade leads to the formation of a velocity gradient inside the fluid, which in turn generates shear force. When the shear force reaches a certain value, it will cause cell damage, which is not conducive to cell culture. The structure and rotation speed of the blade determine the mixing effect and the shear force generated in the reactor. These two factors are often contradictory, that is, when the mixing effect is good, the shear force is large, and when the mixing effect is poor, the shear force is large. The key to the design of the bioreactor blade is how to minimize the shear force generated by stirring while ensuring the mixing effect.

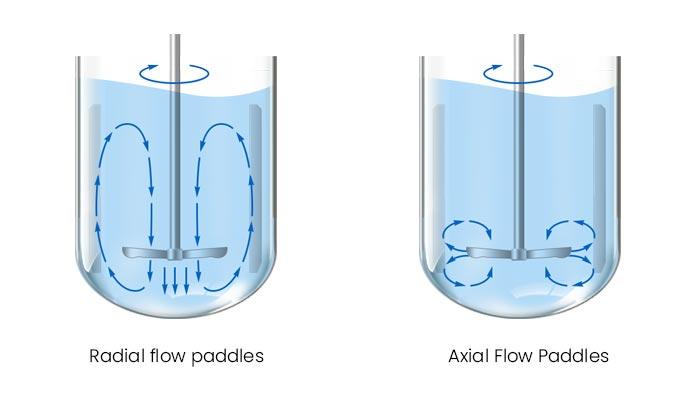

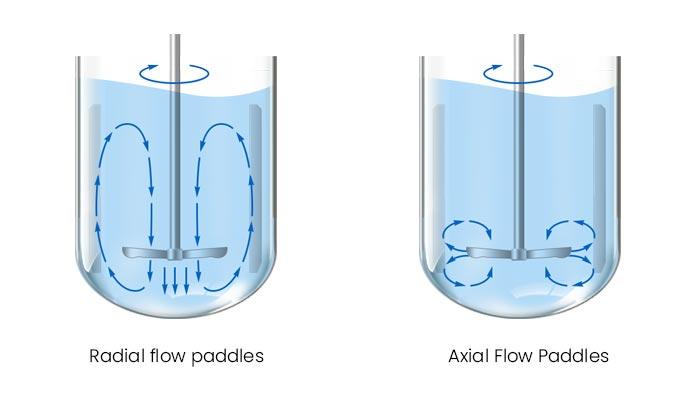

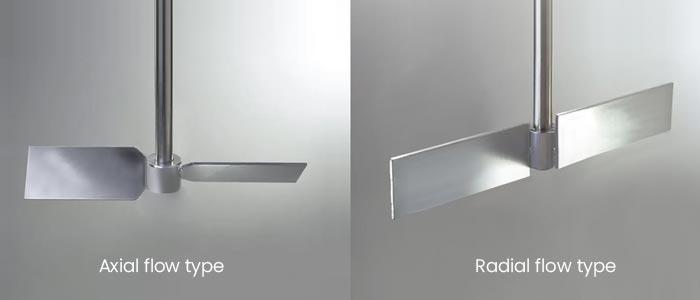

According to the state of liquid flow caused by stirring, the blades can be divided into radial flow blades, axial flow blades and mixed flow blades. The radial flow and axial flow are shown in the following figure.

As shown in the figure, radial flow is formed when the liquid flow is pushed from the shaft of the stirring paddle to the inner wall of the vessel, and axial flow is formed when the liquid flow is pushed up and down along the shaft of the stirring paddle. Mixed flow occurs when there is axial flow.

-

The representative of the current radial flow blade is the Rushton blade

As shown in the figure below, Rushton impellers are now referred to as flat blade or disc turbine impellers. The blades of this kind of stirring paddle are flat and vertically distributed along the stirring shaft. When there is a baffle plate, two circulating flow fields can be formed from the blade as the boundary, and the shear force generated is relatively large. Unidirectional flow, so the mixing effect is also poor, and the viscosity range of the material that can be processed is the widest. Usually, the rotation speed range is 100~600rpm. Based on the above advantages, and the gas absorption process, some gas can be stored under the disc, and the gas dispersion can be more stable. Rushton and other Rushton type stirring paddles are widely used in cells under aerobic conditions that are not sensitive to shear force. Line cultures such as yeast, bacteria, plant cells, and certain molds.

-

The representative blades of axial flow blades are propellers

Also known as a propelling paddle, as shown in the picture below. The front of the blade can be flat or concave, but the back is all concave. When rotating, the liquid is discharged forward in an axial flow to form a circulation in the tank for generating axial flow. This kind of blade has a high circulation speed, but a large amount of circulation, and the shear force generated during stirring is small, but like the radial flow blade, it is a unidirectional flow generated, so the mixing effect is poor, and it is commonly used. For low viscosity fluids, the common speed range is 100~500rpm. This type of paddle and propulsion blades are basically not suitable for gas absorption process, and can only be used when a small amount of easily absorbed gas or a low degree of dispersion is required. It is mainly used for the mixing of liquid-liquid systems, the uniformity of temperature, the prevention of sludge sedimentation in low-concentration solid-liquid systems, etc., or some specific anaerobic cultivation.

-

The representative of the mixed flow blade is the Elephant Ear paddle

As shown in the image below, this type of paddle has flat blades at an angle to the agitator shaft and produces both axial and radial flow. This combined flow can achieve better mixing effect, and the shear force generated is also small, and the rotation speed during operation is generally not high, about 1~100rpm, which is used for low viscosity fluids. When the fan width is 120°, the angle between the blade and the shaft is 45°, and the ratio of the blade diameter to the inner diameter of the tank is 1:3, the Elephant Ear blade has better mixing performance and less damage to cells. , suitable for the culture of animal cells.

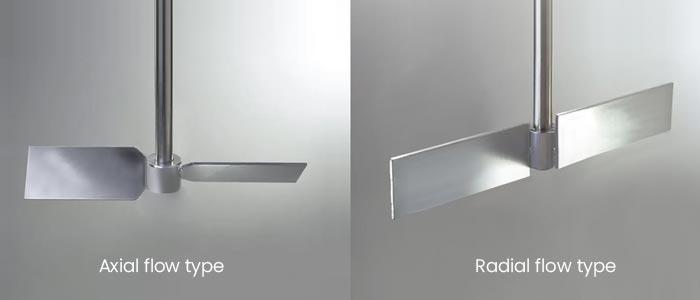

This type usually has only two blades and is the simplest type of stirring blades. According to the vertical or inclined installation of the blades, it can be divided into radial flow type and axial flow type as shown in the figure below. It is mainly used when discharge flow is necessary. Since the power consumption of the axial flow impeller is lower than that of the radial flow under the same displacement, the axial flow impeller is used more. Its main uses are: in the liquid-liquid system, it is used to prevent separation and make the temperature uniform; in the solid-liquid system, it is mostly used to prevent solid sedimentation. However, paddle impellers are not suitable for gas-liquid dispersion and gas-holding and miniaturization operations.

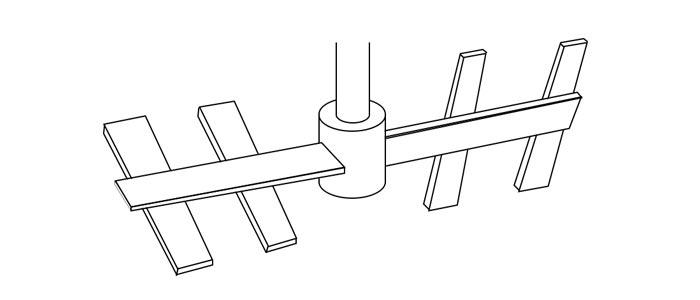

In addition, because it is suitable for making a large blade diameter, it can also be used for stirring high-viscosity liquids. In this case, in order to promote the exchange of liquid up and down, or use 3-5 layers of multi-layer impeller, or use the deformation as shown in the figure below paddle impeller. For low-viscosity liquids, the ratio of the blade diameter to the vessel diameter of the paddle impeller is 0.35~0.5, and for high-viscosity liquids, it is 0.65~0.9; the rotating speed used is 20~100r/min.